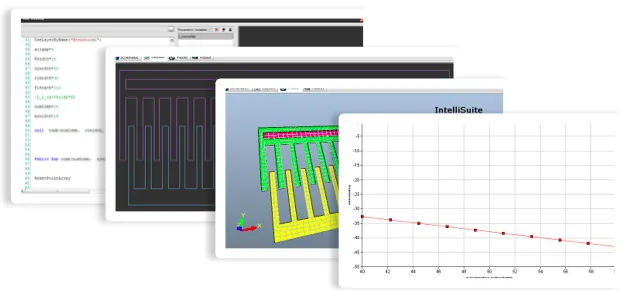

We’re thrilled to unveil the next evolution in MEMS design and simulation – IntelliSuite™ v9.2!

Our platform encompasses the three core pillars of MEMS simulation:

✨ Multiphysics

✨ Microfabrication

✨ System Integration

As the only complete MEMS simulation tool on the market, IntelliSuite™ has been a trusted partner for delivering customized, physics-based solutions validated by experimental data. This commitment has consistently placed us at the forefront of innovation.

What’s new in v9.2?

The latest release focuses on simulation pertinent to photonics and optoelectronics-based materials, opening new horizons for advanced research and industry applications.

Empowering Academic Users.

We believe in providing full software access to empower academic research groups, enabling them to explore industry-ready and needy features and simulations and maximize the tool's potential for their specific needs.

Intellisense will hold IntelliSuite 9.2 webinar on Jan 13, 2025, please register here.

October 9, 2022– IntelliSense has announced the latest major release of its industry-leading software tools for the MEMS community, IntelliSuite v9.1, is available immediately. The new software version includes many updates for the end-to-end design and simulation package.

Interested party can contact Intellisense for further information.

NISKAYUNA, NY – March 2, 2022 – GE Research, a strategic provider of MEMS foundry services, and IntelliSense Software Corporation, a leading MEMS solution provider, today announced a joint activity to enhance the availability of GE’s MEMS foundry process flow called “Polaris,” for the development of MEMS inertial devices of navigation-grade at low cost.

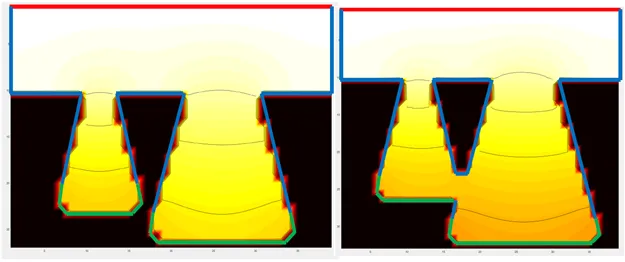

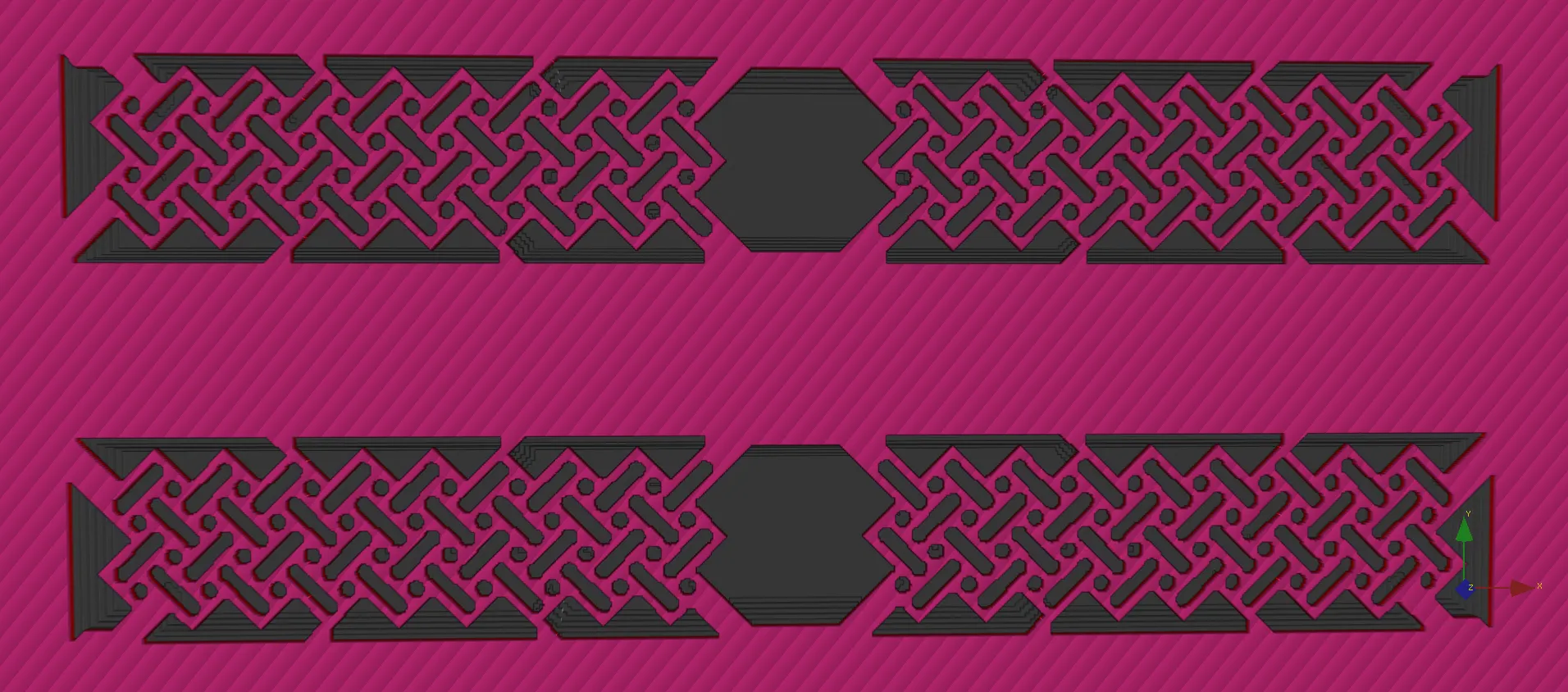

As of today, Intellisense is proud to announce the immediate addition of the 3D gray scale lithography process simulation feature to Intellisuite. This feature allows you to customize and optimize your gray mask in the simulation phase of Intellisuite and to view and analyze the resulting 3D structure before implementing the actual lab work itself, thus saving time and resources. This will also allow designers to be more innovative and bold in their initial ideas and save them for costly mistakes. Finally, this new feature will allow users to consistently create complex grayscale mask files, a previous major barrier in widespread grayscale lithography implementation.

Dr. Holger Klein, director of Chip Design at OE Solutions America Inc., says this about the new simulation feature: “This feature is a critical new addition for our products’ development and optimization, and we are very pleased with the capabilities it brings to exploring various processing options. While working with the Intellisense team, they have addressed our requirements seriously and the result of the development is this great new feature.”

Dr. Sripadaraja. Manager, Application and Sales at Intellisense, remarks this new addition to Intellisuite as “another milestone which shows Intellisense is and continuously will be committed to serving the industry and updating our tools to the ever-changing demands of a modern world.”

With this new addition, we at Intellisense hope to remove the barriers to widespread grayscale lithography implementation and allow companies access to this new exciting lithography technique and the resulting products and market that can come with it.

Thank you everyone for visiting the IntelliSense Booth and learning more about the Fab Simulation tools and the Multiphysics tools of IntelliSuite.The show was a great success, and we look forward to meeting you all for the next grand event.

Lynnfield, MA – February 1, 2019 – IntelliSense has announced the latest major release of its industry-leading software tools for the MEMS community, IntelliSuite v9.0. The new software version includes major updates for the end-to-end design and simulation package. The new IntelliSense v9.0 features state-of-art implementations in its process simulation and multi-physics simulation capabilities to address leading challenges faced by Industries and researchers in MEMS development, while refining and optimizing the already existing algorithms to work more efficiently. The simulation driven MEMS product development is cutting the time and cost involved in product development for many industries by highlighting any process related bottlenecks in their design or process recipes at the early stages of design and process development.

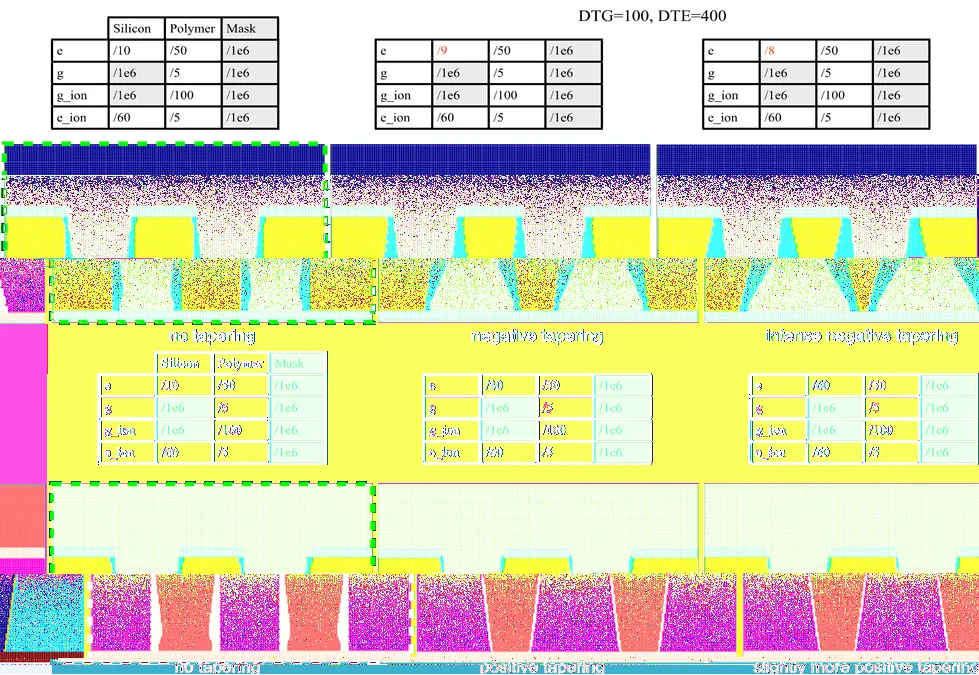

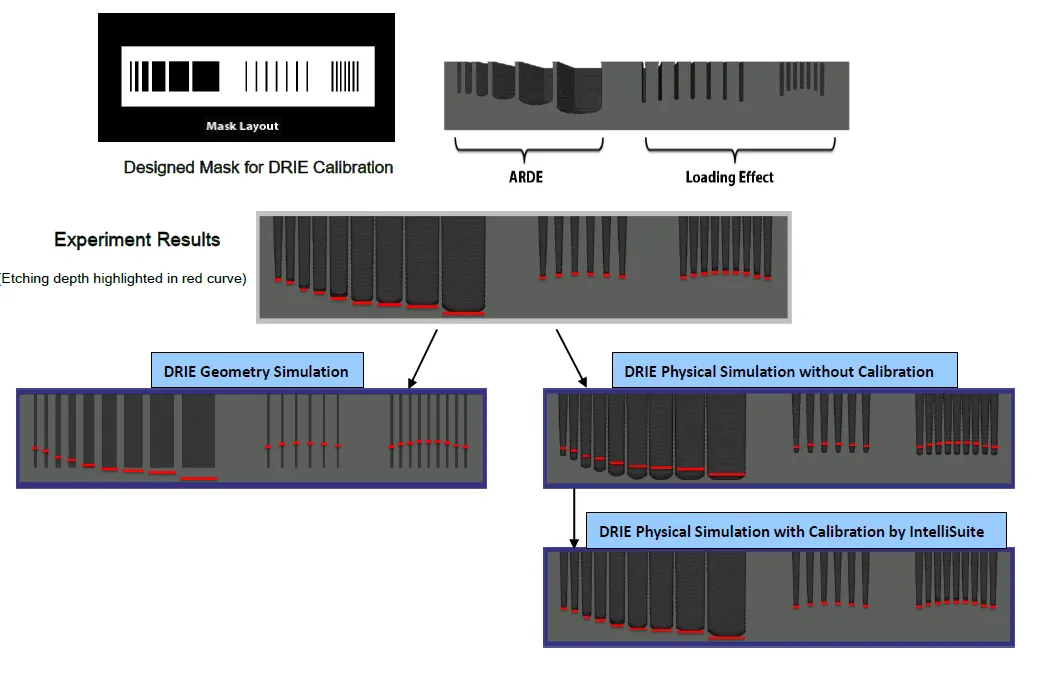

The taper control feature in the DRIE simulator gives the customers an advantage of controlling the process tapering precisely using the six taper parameters incorporated in the model. Along with the ARDE, Lag effect and undercut control calibration, the taper ccontrol calibration gives more accuracy to your simulations.

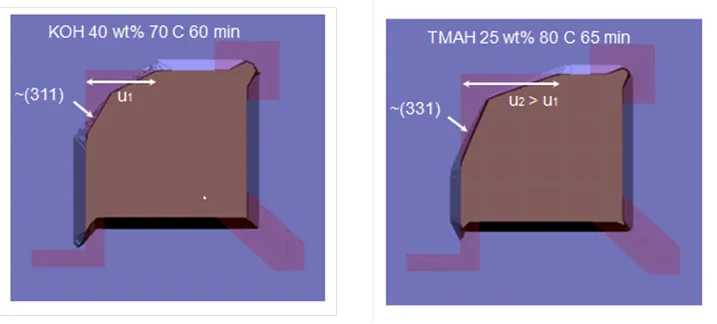

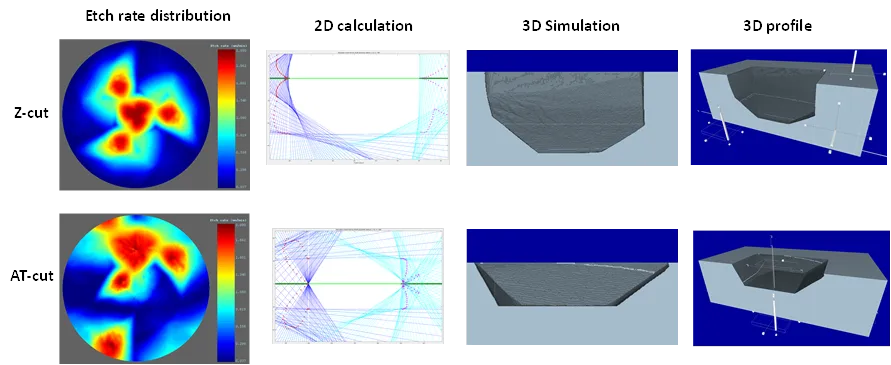

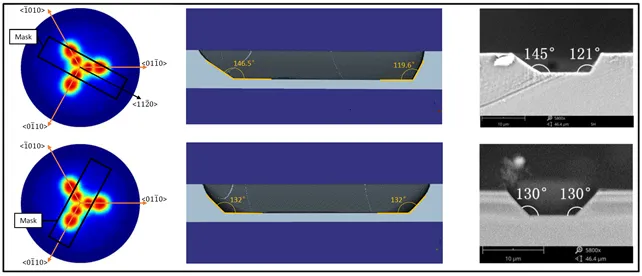

The IntelliSuite process simulation engine, "FabSim", is capable of predicting accurate shapes of etch front during convex corner undercutting of various crystals/substrates based on the etching plane and etchant used. This is achieved by calibrating the etch rate distribution of various processes and updating the material and etchant database in order to render accurate simulations. The material database houses a large number of commonly used crystals/substrates and etchants along with their etch rate distribution databases.

Complex undercutting studies on Si using different Etchants

Quartz Wet Etch Calibration and Simulated Results

Sapphire Wet Etch Calibration and benchmark of simulated results with experiment.

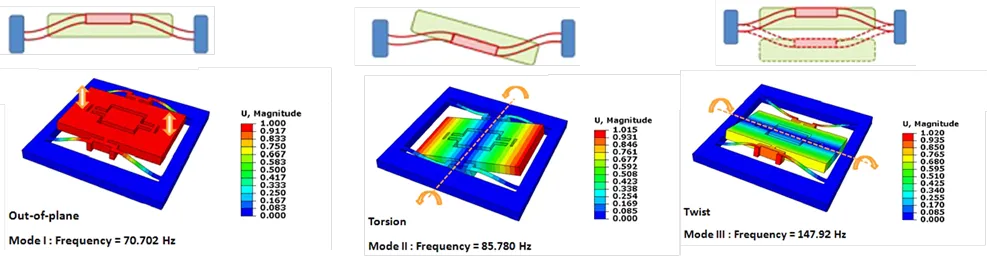

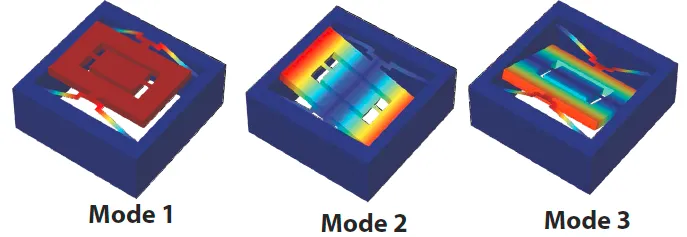

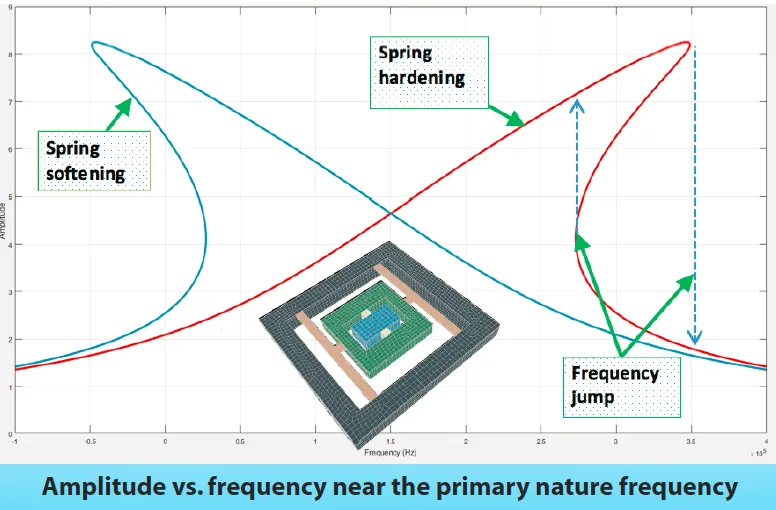

ThermoElectroMechanical (TEM) has updated and revised its nonlinear solver algorithm for faster and more accurate FEA.

Explore and increase your device working bandwidth by studyig the Harmonic and Modal charateristics.

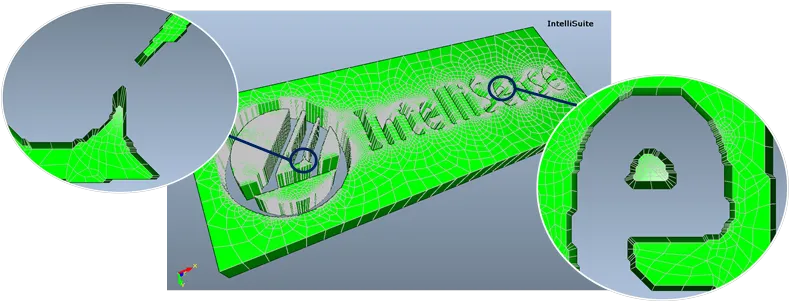

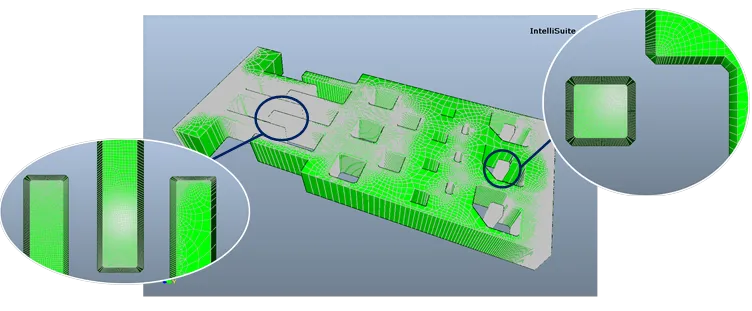

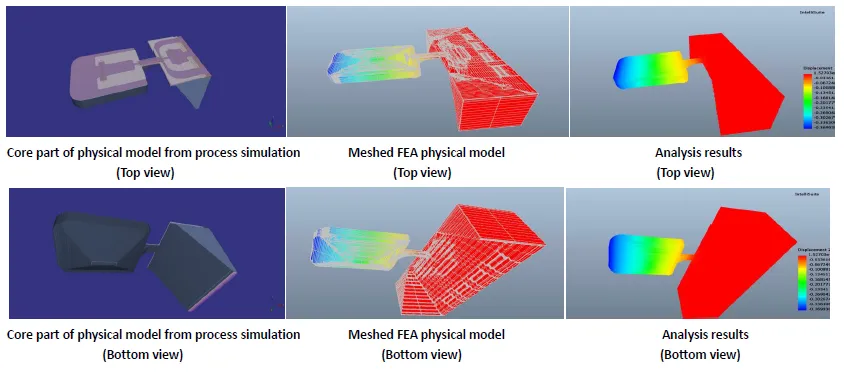

IntelliSuite houses advanced meshing engine algorithm to generate accurate hex mesh to capture complex boundaries of the CAD geometry. The hex engine coupled with the process simulator enables the user to accurately capture imperfections and boundaries in the simulated geometry and export to the FEM Solver to accurately capture the effects of process imperfections in the device characterstics and performance.

Robust Hex Mesh generation enables user to capture the geometry accurately

IntelliSuite is the industry-leading tool set for MEMS layout design, advanced process simulation, FEA, parametric analysis, system simulation, packaging analysis and more. Covering all aspects of the MEMS design cycle, IntelliSuite v9.0 provides a groundbreaking, end-to-end software solution for MEMS professionals. IntelliSense also provides a global One-Stop MEMS Solution with its custom design, consulting and fabrication services. With users in over 30 countries, IntelliSense is the largest MEMS software vendor with its own in-house fabrication facility.

For more information about IntelliSuite v9.0, please contact IntelliSense us at sales@intellisense.com.

Lynnfield, MA – July 26, 2016 – IntelliSense has announced the latest major release of its industry-leading software tools for the MEMS community, IntelliSuite v8.9. The new software version includes major updates for the end-to-end design and simulation package. IntelliSense made its initial announcement at the recent Hilton Head 2016 conference in Hilton Head Island, SC, USA. Now, all IntelliSense customers will have access to the new software version.

“IntelliSuite is more robust and customizable than ever in v8.9,” said Tom Hall, Applications Manager of IntelliSense. “Some main tools including FabSim and ThermoElectroMechanical (TEM) have been overhauled to include new simulation types and calibration capabilities."

“IntelliSuite is an end-to-end set of tools that helps MEMS professionals with every stage of their design cycle. This latest installement of IntelliSuite is the fastest, most accurate and simplest to use version to date.”

Some of the new features in IntelliSuite v8.9 include:

The ARDE (Aspect Ratio Dependent Etching) or lag effect are normal phenomenon during DRIE. With IntelliSuite Cleanrooms Calibration tool, users can quickly view photorealistic results using physics-driven simulation.

ThermoElectroMechanical (TEM) includes new analysis methods for dealing with nonlinear MEMS systems.

By using FabSim and MeshManipulator, users can now simply and quickly mesh their final processed model. Once the process simulation is completed, the user can customize the mesh for the entire model or an extracted submodel. The final meshed model will automatically open in TEM for multiphysics simulation.

IntelliSuite is the industry-leading tool set for MEMS layout design, advanced process simulation, FEA, parametric analysis, system simulation, packaging analysis and more. Covering all aspects of the MEMS design cycle, IntelliSuite 8.9 provides a groundbreaking, end-to-end software solution for MEMS professionals. IntelliSense also provides a global One-Stop MEMS Solution with its custom design, consulting and fabrication services. With users in over 30 countries, IntelliSense is the largest MEMS software vendor with its own in-house fabrication facility.

For more information about IntelliSuite v8.9, please contact IntelliSense us at sales@intellisense.com.

A closely contested competition consisting of nine teams, comprising a total of fourteen students, was held on June 3, 2014. For the contest, students were to design and measure (on-site) an RF MEMS tunable notch filter to reduce interference at GPS frequencies. The judges for the event were drawn from the ranks of industry and government. The top three winning teams were each awarded cash prizes and a one-year IntelliSuite MEMS software license. The winners were:

1st Place: Mark Hickle, Purdue University, USA

2nd Place: Kevin Yang, University of Waterloo, Canada

3rd Place: Mehdi Nosrati and Nahid Vahabisani, University of Alberta, Canada

For more information, about IMS2014, click here .

Event organized by:

Semiconductor foundries, such as Taiwan Semiconductor Manufacturing Company (TSMC) in Taiwan, have become an integral part of the ecosystem surrounding ‘fabless’ electronics companies producing large volume integrated circuits (ICs). This paradigm traditionally exploited the partitioning of the design and fabrication disciplines, as well as the economies of scale enabled by a dedicated fabrication facility utilising common processes to mass produce a variety of end ICs. Similarly, the ecosystem of MEMS foundries has followed this partitioning among disciplines, as typified by TSMC’s MEMS foundry services, Innovative Micro Technology (IMT) in Santa Barbara, California, Tronics in Texas and others. The standardisation of MEMS processes, however, is not trivial, given the multiplicity of device operating principles, which rely on a large number of scientific disciplines, physical principles, design methods, fabrication processes and materials. Enter IntelliSense Total MEMS Solutions.

Figure. IntelliSense project process model.

The Total MEMS Solutions paradigm is a new concept in MEMS services, which provides the MEMS market with the expert support needed to take their ideas and concepts to market, beginning with its world-class modelling, simulation and design MEMS software, MEMS device design services, customised MEMS software development, MEMS device prototyping and traditional MEMS foundry services. Many customers have benefitted from IntelliSense Total MEMS Solutions. In one instance, a company required the development of special wet etch technology to enable timely delivery of its latest medical MEMS device. IntelliSense delivered IntelliEtch,an anisotropic wet etch simulator for silicon and quartz, together with Blueprint, a unique MEMS mask layout tool with a built-in DRC tool. Using these tools, the client worked with IntelliSense engineers to design their multistep etch process and achieve their desired wet etch surface profile. In addition, IntelliSense helped the client to extract their own unique, proprietary etch rate database, so they could remain competitive. Along with software and fabrication services, IntelliSense has also been able to assist clients in navigating the market to find more cost-effective solutions while protecting their IP, all without sacrificing performance. With operating entities in both the US and China, world-class designers and a state-of-the-art facility, IntelliSense provides its solutions globally.

The whole article is available from the digital version of the April issue of Commercial Micro Manufacturing magazine. To access it, click here and go to page 39.

Woburn, MA – February 3, 2014 – Today, IntelliSense announced a major release of its industry-leading software tools for the MEMS community, IntelliSuite v8.8. The new IntelliSuite version includes major updates for all software modules and the addition of a new tool, Parametric Designer. IntelliSense made its initial announcement at the recent IEEE MEMS 2014 conference in San Francisco, CA. Now, all IntelliSense customers will have access to the new software version.

“Each IntelliSuite module has been updated in IntelliSuite v8.8,” said Tom Hall, Applications Manager of IntelliSense. “Our users will have access to the same tools they know and love, but will notice some major enhancements and the addition of a new tool, Parametric Designer, which enables users to easily perform unattended parametric analyses.”

“IntelliSuite is an end-to-end set of tools that helps MEMS professionals with every stage of their design cycle. This is by far the most accurate, fastest, and easiest-to-use version of IntelliSuite to date.”

Parametric Designer is the newest addition to the powerful family of IntelliSuite tools. This customized parametric analysis tool accepts a VBS file, then generates masks, 3D models and meshes automatically. Once the user applies boundary conditions and loads, Parametric Designer performs simulations then gives a detailed result report.

Users can now handle meshing larger models automatically with the new 64-bit version of the Hexpresso mesh engine.

The Blueprint layout editor has some new drawing features, including an image import option that lets users add JPG, PNG and BMP images into their current layout.

The RECIPE™ simulator can now perform DRIE simulations with unparalleled accuracy with the new DEEP-RIE calibration tool. IntelliEtch™ also has a new calibration tool, Wagon Wheel Analyzer II which helps users extract etch rates accurately.

ThermoElectroMechanical™ has been updated to perform simulations on magnetostrictive devices. The ElectroMagnetic Analysis™ tool has also received several updates for enhanced accuracy and usability.

IntelliSuite is the industry-leading tool set for MEMS layout design, advanced process simulation, FEA, parametric analysis, system simulation, packaging analysis and more. Covering all aspects of the MEMS design cycle, IntelliSuite 8.8 provides a groundbreaking, end-to-end software solution for MEMS professionals. IntelliSense also provides a global One-Stop MEMS Solution with its custom design, consulting and fabrication services. With users in over 30 countries, IntelliSense is the largest MEMS software vendor with its own in-house fabrication facility.

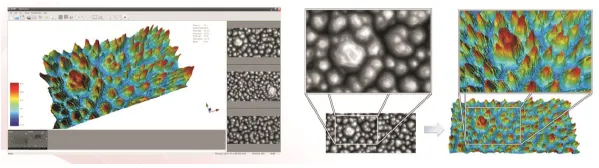

Woburn, MA – June 4, 2013 - Today, IntelliSense announced a new addition to its market –leading line of tools for the MEMS industry. The new tool, NanoViewer enables users to conveniently view the 3D reconstruction of SEM images of micro-nano structures.

NanoViewer is the newest addition to IntelliSense’s strong suite of design and simulation tools. Created in collaboration with Dr. Alice Zhang’s research group at Peking University’s Institute of Microelectronics and their partners, NanoViewer offers MEMS engineers countless benefits. With NanoViewer, making comparisons among different silicon samples has never been simpler or more efficient.

Tom Hall, IntelliSense’s applications manager, will be demonstrating NanoViewer at the Transducers 2013 conference in Barcelona, Spain (June 16-20). Attendees can see NanoViewer in action at the IntelliSense exhibition booth. For more information about NanoViewer and the IntelliSuite family of tools, contact Tom Hall (information listed below).

IntelliSense ignited the MEMS industry in the early 1990s with its IntelliSuite® family of innovative CAD tools -- and is now the leading innovator and supplier of design and development solutions for the MEMS professional. After almost two decades in continuous development, IntelliSuite now boasts the widest range of features available in a MEMS tool and remains unsurpassed in its simulation capabilities, robustness and ease of use. With users in more than 35 countries, IntelliSuite is the industry-standard software for MEMS. IntelliSense also offers custom design and prototyping services to universities, blue-chip companies and start-ups worldwide.

Contacts

IntelliSense

Tom Hall, 781-933-8098 ext. 6007

info@intellisense.com

After attending the IEEE MEMS 2013 conference, IntelliSense’s Tom Hall led a full-day training workshop at the National Center for High Performance Computing (NCHC) for the Taiwan MEMS community. The three part workshop started off with a detailed introduction to IntelliSuite v8.7 and its new modules. Next, the workshop focused on a collection of MEMS design cases. Using IntelliSuite design and simulation tools, examples included were:

The workshop ended with some hands-on guided examples. Workshop attendees were taught some basics of building a process flow in IntelliFab and simulating their flow’s fabrication using FabSim. Another example introduced some drawing features of Blueprint as attendees designed comb drives using both standard drawing tools and some VBScript from Blueprint’s database. The event was well-attended by several MEMS researchers and MEMS industry professionals.

For more information about NCHC, visit www.nchc.org.tw/en/

Woburn, MA – February 6, 2012 – Today IntelliSense announced a major new version of its market-leading software for the MEMS industry, IntelliSuite v8.7. IntelliSuite v8.7 includes upgrades to almost every module of IntelliSuite and introduces several groundbreaking industry-first features.

“Every IntelliSuite module has been updated in IntelliSuite v8.7,” said Joe Johnson, Business Development Manager of IntelliSense. “Our customers will notice a large increase in IntelliSuite’s capabilities, and at the same time, the software has been made easier to use. From accuracy, stability, and speed improvements to brand-new, industry-first functionality, this is by far the best version of IntelliSuite, yet.”

“In addition to the latest version of IntelliSuite, we are launching FabSim and Exposure, two new process simulators that will make any process engineer’s job easier,” said Johnson. “FabSim is a unique process flow simulator that enables users to fully simulate the physical fabrication process, rather than settle for crude process emulation. Exposure is a powerful lithography simulator that will allow users to simulate full lithography processes in minutes.”

Some of the new features in IntelliSuite v8.7 include:

Exposure is a new addition to IntelliSense’s strong suite of process simulation tools. This deep resist/SU8 simulator can accurately model lithography processes like exposure, post-exposure bake, and development. The dynamic cellular automata simulator and included material databases ensure robust and speedy lithography simulations.

IntelliSense has long been the MEMS industry’s leader in physical process simulation, with tools like RECIPE for DRIE etch simulation, IntelliEtch for wet etch simulation, and Exposure for lithography simulation. All of this functionality is now integrated into IntelliSuite’s flagship new process simulator, FabSim. FabSim enables users to quickly create photo-realistic process models and cross-sections using full physical simulation, rather than simple process emulation.

The industry’s most powerful wet etch simulator can now simulate anisotropic etching of quartz in addition to silicon. Features that IntelliEtch is known for, like etching of high-order planes and multi-masking, are made easier to use in a huge interface update. The new GPU-based simulator can run etch simulations over 100 times faster than the previous CPU-based version.

IntelliSuite’s state-of-the-art automeshing tools are again updated with cutting-edge advancements. Material properties and boundary conditions can be automatically applied when a 3D meshed model is generated. New adaptive meshing and mesh refinement settings allow users to have full control over the automated meshing process. Meshing is now faster and more robust than ever before.

The original MEMS multiphysics simulator has received some powerful updates in IntelliSuite v8.7. New coupled package-device simulation capability can be used to analyze packaging effects on a MEMS device. Dynamic contact analysis can be used to simulate models with multiple points of contact. IntelliSuite’s powerful reduced-order macromodel extractor can now generate piezoelectric as well as multi-contact macromodels. In addition, the finite element solver has been updated to ensure greater stability and simulation accuracy.

IntelliSense ignited the MEMS industry in the early 1990s with its IntelliSuite® family of innovative CAD tools — and is now the leading innovator and supplier of design and development solutions for the MEMS professional. After almost two decades in continuous development, IntelliSuite now boasts the widest range of features available in a MEMS tool and remains unsurpassed in its simulation capabilities, robustness and ease of use. With users in more than 35 countries, IntelliSuite is the industry-standard software for MEMS. IntelliSense also offers custom design and prototyping services to universities, blue-chip companies and start-ups worldwide.

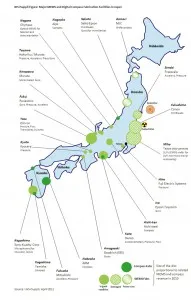

Nearly two months after the Japan quake and tsunami wreaked havoc on the world’s industrial supply chains, the global microelectromechanical system (MEMS) industry is back on its feet, emerging relatively unscathed after the potent disaster, according to new IHS iSuppli research.

To date, the supply of MEMS sensors and actuators remains only slightly affected, with the main effect of the Japanese earthquake on the world MEMS industry impacting the demand side, not on supply. Manufacturers with damaged factories are more severely impacted than suppliers, or bottlenecks elsewhere in the supply chain are affecting the production of manufacturers.

MEMS devices are used in popular consumer electronic products like smartphones and tablets, and the components also find their way into applications for the industrial, medical and aerospace sectors. Given that nine out of the top 50 MEMS manufacturers worldwide are Japanese companies, and with Japan serving as a strong manufacturing base for MEMS companies headquartered in Western countries, the world’s third-largest economy holds a central position in the production and supply of MEMS.

Japanese companies sold some $1.38 billion worth of MEMS in 2010, or 21.3 percent of the world’s market requirement. Canon, Panasonic, Epson and Denso all rank among the Top 20 in the global MEMS space.

Approximately 32.5 percent of MEMS sensors and actuators in value were processed—either partly or entirely—in Japanese facilities in 2010, corresponding to revenues from both Japanese MEMS companies and from foreign companies that have their MEMS processed in Japan. Western companies with MEMS facilities in Japan include Freescale Semiconductor, Knowles Electronics, Goodrich Corp. and Texas Instruments Inc. for the Complementary Metal-Oxide Semiconductor (CMOS) circuitry of its Digital Light Processing (DLP) chipsets.

Furthermore, Japan made nearly all the world’s digital compasses, a device rapidly becoming a standard feature in tablets and cell phones equipped with Global Positioning System (GPS) functionality. Worldwide shipments for digital compasses reached 263 million units in 2010, up 354 percent from 58 million the earlier year, with shipments expected to rocket to 1.28 billion units by 2015, IHS iSuppli research bears out. Together, four Japanese firms—AKM Semiconductor, Yamaha Corp., Aichi Steel and Alps Electric—made 97 percent of the global supply of digital compasses.

For the MEMS industry in general and for Japan’s MEMS sector in particular, damage was not as severe as encountered by other industries because of a happy accident in geography. Most MEMS fabs and foundries are located in southern Honshu, away from the disaster-devastated northern section of the island. Moreover, MEMS and compass suppliers had been relying on multiple fabrication plants for manufacturing even before the quake and tsunami occurred.

Damage Report: Only Three Fabs Sustained Direct Damage

Only three of the 22 most important MEMS and compass fabrication plants in Japan suffered direct damage, IHS iSuppli research shows, although 19 fabs potentially could be affected by the same logistical and power issues impacting all Japanese industries in the calamity’s aftermath. The three damaged facilities belonged to Freescale, Canon Corp. and Texas Instruments.

According to Freescale, the company has decided to close its 150-millimeter (mm) fab in Sendai, near the quake’s epicenter, and focus efforts on accelerating the transfer of MEMS production to its 200-mm Oak III fab in Texas. Freescale was lucky in that the Sendai fab had been scheduled for shutdown by the end of 2011, and the company already had built buffer inventories. Had it not taken this decision in 2009, Freescale and its customers would have been severely hurt, IHS believes.

For Canon, which makes printers and MEMS print heads in the city of Fukushima, site of the nuclear meltdown, production was halted after significant damage to the company’s plant. However, Canon managed to repair the damage very quickly, with the plant completely operational again by the first week of April. As a result, the impact of the disaster on Canon’s MEMS revenue for 2011 is expected to be very modest, IHS iSuppli data indicate.

For its part, Texas Instruments’ Miho fab northeast of Tokyo has repaired various infrastructure systems for water, gases and chemicals. Full production will resume by the middle of July, with full shipment capacity to commence before September, said the company. Prior to the catastrophe, Texas Instruments already was using multiple fabs for the fabrication of CMOS wafers for DLP MEMS chips, and the company is in a fortunate position to rapidly increase production at its other fabs to compensate for the disruption at Miho.

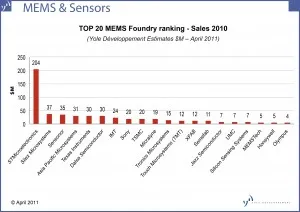

STMicroelectronics continued to dominate the MEMS foundry business, capturing nearly a third of the total foundry market, but there was plenty of re-shuffling among the rest of the leading players in this highly fluid sector. Silex Microsystems saw robust 85% growth to some $37 million in sales, to become the largest of the pure play independents, largely on demand for its via-first, highly doped silicon TSV technology. Sales at Asia Pacific Microsystems jumped some 60%, to move the Taiwan company into fourth position.

But in a market largely driven by demand for high volume sensors for smartphones and other consumer gear, large MEMS IDMs with 8-inch lines and assured supply capability captured much of the new business. The IDMs also benefited from the robust recovery of the automotive market, as those qualified devices remain largely made in house. Smaller fabless companies generally saw slower growth, as they had to compete with the giants for volume orders. “In the future, the large IDMs like Bosch, STMicroelectronics and Panasonic will continue to capture much of the big growth in consumer MEMS markets,”said Jean Christophe Eloy, CEO and President of Yole Développement. “And those foundries coming from the large volume semiconductor industry will become more and more important. The foundry business will increasingly be in other hands than before, as much of the growth will be captured by new players.”Yole Développement estimates TSMC roughly doubled its MEMS revenues last year, to jump from about $10 million to about $20 million in MEMS foundry revenues. Other semiconductor industry companies like XFab, Jazz Semiconductor and UMC also saw healthy growth, though remain relatively smaller players. Though not yet large enough to make the list, SMIC’s MEMS foundry business is also growing, and Global Foundries plans an aggressive move into the MEMS market.

Though the specialty MEMS foundries may be serving lower volume customers, those applications include much specialized, higher margin business in optical, telecommunications and biomedical applications. “These foundries may not be seeing the same big growth, but they are making a good, profitable business,” says Eloy. And there’s a large and growing group of these larger specialty foundries increasingly separating themselves from the pack. Nine MEMS foundries now have revenues of about $20 million or more, and six of those are now doing more than $30 million in annual business. As recently as 2006, only five MEMS foundries reached the $20 million mark.

Sensonor vaulted onto the list in number third position, with $35 million in foundry business, as Infineon spun out the MEMS unit to make its tire pressure monitoring systems as a foundry. Texas Instruments, meanwhile, slipped to fifth place from second, on the slowing of demand for ink jet heads from Lexmark, as the maturing inkjet printer market slowed and transitioned from disposable to permanent heads.

IntelliSense ignited the MEMS industry in the early 1990’s with its IntelliSuite family of innovative CAD tools

February 7, 2012 - We are excited to announce that Lyn Bursey, Senior Metrology Technician, and Ed Dukats

February 6, 2012 - (Atlanta, GA) ClassOne Equipment expands staff to service and support KLA-Tencor legacy tools to address growing demand.

September 27, 2011 - ALBANY — Gov.

July 28, 2011 - ClassOne Equipment (Atlanta, GA) announced that it has achieved an industry milestone in the refurbished Semiconductor and MEMS equipment market with the recent sale of its 150th mask aligner to the Smart System Technolo

July 21, 2011 - (Atlanta, GA) Refurbished equipment supplier, ClassOne Equipment, reported 135 percent revenue growth in 2010 over 2009, which is nearly double the 77 percent segment growth rate recently reported by Semico Research.

July 14, 2011 - (Atlanta, GA) ClassOne Equipment is pleased to offer mature semiconductor FABs, MEMS start-ups, LED manufacturers and other emerging technology companies an extensive inventory of high quality refurbished mask

In this webinar, we will delve into a comprehensive exploration of the extensive benefits offered by the IntelliSuite software across different research levels in MEMS, spanning from academic pursuits to industrial applications. Our discussion will cover diverse aspects of the MEMS development cycle, addressing key stages from initial design concepts to the development of Process Design Kits (PDK), virtual fabrication processes, and simulations. The software plays a pivotal role in streamlining and simulating fab processes, enabling a thorough assessment before actual implementation.

In this webinar, we will explore in detail on how IntelliSuite software can be beneficial and help through various verticals of MEMS development cycle. From design concept, to various Process design kits development (PDK), virtual fabrication process and simulation, Multiphysics and System Integration/3D package analysis. While the software can help streamline/simulate the process recipe in fab before actual process, it also meshes the process (fab) model to run multi physics FEM simulation to make the designed device more manufacturable. and achievable in performance. Further through the reduced order model simulation and links it to circuit EDA tools to make the system designer can design control and sense circuit more precisely . The open architecture allows the Intellisuite can help with various non traditional silicon sensor and actuator device design (beyond silicon), such as quartz, InP, sapphire etc. also it allows non traditional process simulation, as angled Ion Beam Etching (IBE), 3D lithography, 3D oxidation, high order index substrate wet etch (Si/Quartz) etc.

Speaker Profile – Dr. Sripadaraja, the Manager of Applications and Sales at IntelliSense Software, Lynnfield, MA. Dr Sripadaraja is responsible for the development of business for MEMS software package IntelliSuite. He has about over 10 years of experience in design/fabrication and development of MEMS devices using IntelliSuite, he holds his Ph.D from National Institute of Technology, Karnataka, India.

IntelliSense will be exhibiting at the 37th IEEE International Conference on Micro Electro Mechanical Systems. The IEEE International Conference on Micro Electro-Mechanical Systems (IEEE MEMS) is one of the premier annual events reporting research results on all scientific aspects of micro/nano-scale devices, micro/nano-systems, as well as their relevant technologies and industrial trends. This conference brings together the nanotechnology research communities to discuss the latest successful advancements in MEMS. IEEE MEMS 2024 will be held in Austin, Texas, USA, from 21 to 25 January 2024. Our experts will showcase our latest IntelliSuite software features and innovative MEMS solutions. We will welcome you at booth 24!

The IntelliSense Software Japan team gathered together in Tokyo for the release of IntelliSuite v9.0 in the Japan Market on July 05, 2019.

IntelliSense will be exhibiting at IEEE Inertial 2019. It is the 6th Annual IEEE International Symposium bringing together professionals from the MEMS Inertial devices community. Focusing on the innovations and current research in the Inertial devices sector, this confernece will build a platform for the academic researchers to connect with the MEMS Industrial Professionals. This conference will be held between April 1-5, 2019, at Naples, Florida, USA.

IntelliSense will be exhibiting at the 32nd IEEE International Conference on Micro Electro Mechanical Systems. This confernece (MEMS 2019) is one of the premier annual events reporting research results on every aspect of Microsystem technologies. This confernece reflects from the rapid proliferation of the commitment and success of the MEMS research and industry.

the IEEE MEMS Conference has attracted more than 700 participants, 800+ abstract submissions and has created the forum to present over 200 select papers in podium and poster/oral sessions. Its single-session format provides ample opportunity for interaction between attendees, presenters and exhibitors. MEMS 2019 will be held in Seoul, Korea, from 27-31 January 2019.

IntelliSense will be exhibiting at Microtech Innovation Summit 2019. This conference brings togethr the greatest minds in the MEMS, Sensors and microtechnology industry. The confernece will also bring together the world leading venture professionals, capital, innovation, M&A and other technology professionals focusing in MEMS and Sensors. During this confernece, IntelliSense is planning to make an impactful presense by demonstrating the groundbreaking and state-of-art capabilities of the IntelliSuite Suite software for Design, Process Simulation and Multiphysics Analysis of MEMS devices. The summit is scheduled between November 5-7, 2019 at San Jose, CA.

IntelliSense will be exhibiting at MEMS 2018. Experiencing many years of strong commitment and immense growth, the IEEE MEMS conference series has evolved into a premier annual event in the MEMS area. The 31st IEEE International Conference on Micro Electro Mechanical Systems (MEMS 2018) will report the latest research results on every aspect of Microsystems technology, reflecting the continuing commitment and success of the international MEMS community. In recent years, the IEEE MEMS Conference has attracted more than 700 participants along with over 800 abstract submissions, and has created the forum to present over 200 selected top-quality papers in podium and poster/oral sessions. Its technical sessions provide ample opportunity for interaction between attendees, presenters and exhibitors. MEMS 2018 will be held in Belfast, UK, from January 21 - 25, 2018.

IntelliSense will be exhibiting at MEMS 2017. Experiencing many years of strong commitment and immense growth, the IEEE MEMS conference series has evolved into a premier annual event in the MEMS area. The 30th IEEE International Conference on Micro Electro Mechanical Systems (MEMS 2017) will report the latest research results on every aspect of Microsystems technology, reflecting the continuing commitment and success of the international MEMS community. In recent years, the IEEE MEMS Conference has attracted more than 700 participants along with over 800 abstract submissions, and has created the forum to present over 200 selected top-quality papers in podium and poster/oral sessions. Its technical sessions provide ample opportunity for interaction between attendees, presenters and exhibitors. MEMS 2017 will be held in Las Vegas, NV, from January 22 - 26, 2017.

IntelliSense is proud to sponsor MME 2017. The 28th edition of the long-established Micromechanics and Microsystems Europe Workshop will be held in Uppsala, Sweden from August 25-27th, 2017. Showcasing the newest developments in microsystems technology and applications, the gathering will provide a platform to facilitate interdisciplinary communications and generate new collaborations between delegates from both academic and industrial backgrounds.

MME is traditionally structured so that attendees can meet in a friendly and relaxed atmosphere, and the emphasis lies on informal discussions around poster presentations rather than on formal oral presentations. A small number of world leading experts are invited to review key research topics in plenary presentations, while all other delegates are given an opportunity to present research highlights in a rapid oral format followed by an interactive poster discussion.

For more information about MME 2017 Click here

Click here to register.

Payment details will be provided to the registering participants. For more information, please contact india@intellisense.com

IntelliSense is proud to sponsor MME 2016. The 27th edition of the long-established Micromechanics and Microsystems Europe Workshop will be held in Cork, Ireland from August 28-30th, 2016. Showcasing the newest developments in microsystems technology and applications, the gathering will provide a platform to facilitate interdisciplinary communications and generate new collaborations between delegates from both academic and industrial backgrounds.

MME is traditionally structured so that attendees can meet in a friendly and relaxed atmosphere, and the emphasis lies on informal discussions around poster presentations rather than on formal oral presentations. A small number of world leading experts are invited to review key research topics in plenary presentations, while all other delegates are given an opportunity to present research highlights in a rapid oral format followed by an interactive poster discussion.

The event will be held at the CIT Cork School of Music – an international centre of musical excellence located within the centre of Cork City and overlooking the River Lee.

CIT Cork School of Music

Union Quay

Cork, Ireland

Phone: +353 21 480 7310

For more information about MME 2016, Click here

IntelliSense will attend the SIMULIA Alliances Partner Meeting on May 23, 2016. The purpose of the meeting is to connect Alliance Partners and share information and developments from SIMULIA, specifically as it relates to the SIMULIA Ecosystem.

The meeting will take place in at the beginning of Dassault Systèmes Science in the Age of Experience event.

Boston Marriott Copley Place

110 Huntington Avenue

Boston, MA 02116, USA

Phone: 1-617-236-5800

Click here for more information about the event, Click here

IntelliSense will be exhibiting at MEMS 2014. Over the past twenty-five years, the IEEE MEMS Conference series has been the flagship annual event of the MEMS community. The 27th IEEE International Conference on Micro Electro Mechanical Systems (MEMS 2014) will report research and development results on every aspect of MEMS and Microsystems Technology, reflecting on the strong commitment and continuing success of the international MEMS community. In recent years, the IEEE MEMS Conference has created the forum for over 200 top-quality papers, selected from over 800 abstract submissions, in non-overlapping oral and poster sessions, and attracted more than 700 participants. Its single-session format provides ample opportunity for strong interaction between attendees, presenters and exhibitors. MEMS 2014 will be held in San Francisco, California, USA, from January 26 - 30, 2014.

For more information about MEMS 2014, Click here

IntelliSense is an exhibitor at the seventeenth Hilton Head Workshops on the science and technology of solid-state sensors, actuators, and microsystems, which will be held on June 5 - 9, 2016. The Hilton Head Workshops have provided a highly interactive forum for North, Central and South American researchers to present and discuss recent advances in microfabrication technologies for sensing and actuation devices and microsystems for physical, chemical, and biological applications.

Sonesta Resort

130 Shipyard Drive

Hilton Head Island, SC 29928

Phone: 1-843-842-2400

Fax 1-843-842-6503

For more information, visit www.hiltonhead2016.org

IntelliSense will be exhibiting at MEMS 2016. Experiencing twenty-seven years of strong commitment and immense growth, the IEEE MEMS conference series has evolved into a premier annual event in the MEMS area. The 29th IEEE International Conference on Micro Electro Mechanical Systems (MEMS 2016) will report the latest research results on every aspect of Microsystems technology, reflecting the continuing commitment and success of the international MEMS community. In recent years, the IEEE MEMS Conference has attracted more than 700 participants along with over 800 abstract submissions, and has created the forum to present over 200 selected top-quality papers in podium and poster/oral sessions. Its technical sessions provide ample opportunity for interaction between attendees, presenters and exhibitors. MEMS 2016 will be held in Shanghai, China, from January 24 - 28, 2016.

For more information, visit http://www.mems2016.org

IntelliSense will be exhibiting at Innovation 360 in Gatineau, Québec on September 28th and 29th. This annual flagship event draws more than 300 attendees from academia, industry and government, all sharing a common interest in microsystems and nanotechnology. This year's theme will be Connecting to Tomorrow's Technology.

For more information, visit www.innovation360.ca

IntelliSense will be exhibiting at TRANSDUCERS 2015 in Anchorage, AK. The Transducers conference is the world premiere conference in MEMS sensors, actuators and integrated micro and nano systems. The four-day event will showcase major technological, scientific and commercial breakthroughts in mechanical, optical, chemical and biological devices and systems using micro and nanotechnology. Work of both a fundamental and applied nature will be featured.

For more information, visit www.transducers2015.org

MEMS Technical Congress is a one-of-a-kind technical conference, with a focus on discussing critical MEMS and sensors supply chain challenges. This workshop is a place for neutral discussion of pre-competitive issues affecting MEMS and sensors manufacturing and brings together foundries, equipment vendors, research groups, large companies, start-ups, buyers, suppliers, and other stakeholders for solutions knowledge, networking and resources to support your company’s imminent MEMS and sensors commercialization needs. MIG members will also get an exclusive tour of Draper Laboratory along with Bostons historic Fenway Park!

Organized and produced by:

For more information, visit www.memsindustrygroup.org

IntelliSense will be attending TechConnect World Innovation 2015 at the Gaylord National Convention Center near the Washington D.C. National Harbor. There, they will give a talk on process simulation techniques and their impacts on R&D costs. It will showcase some IntelliSuite Cleanroom tools, such as IntelliEtch and FabSim. The presentation will take place during the "Modeling & Simulation of Microsystems" symposium.

The TechConnect World Innovation Conference is an annual event uniquely designed to accelerate the commercialization of innovations out of the lab and into industry. The Technical Program spotlights applications focused innovations, materials and devices emerging from industrial, government and academic laboratories worldwide. The Innovation Partnering Program gathers market-ready, commercially-viable, innovations into the largest global technology accelerator program. Early-stage companies are reviewed and selected by the board of corporate and investment partners. Technical submissions are reviewed and selected by the symposium chairs and program review committee. The 2015 TechConnect World Innovation event encompasses the 2015 SBIR/STTR National Conference, the 2015 National Innovation Summit and Showcase, and Nanotech2015 – the world’s largest nanotechnology event.

For more information, visit www.techconnect.org

IntelliSense will be participating in the 2014 UGIM Symposium. The goal of this symposium is to bring together leading educators and researchers from university, government, and industry around the world to discuss issues related to R&D cleanroom laboratories and trends therein. Representatives of university micro/nano fabrication facilities, ranging from new labs to nationally recognized facilities, have found this symposium an excellent forum for exchanging information and presenting new research and educational concepts. Industry interactions with universities, including technology transfer, collaborative research, and training efforts are frequently presented.

Harvard University

Presentations 8:00am-5:00pm

Northwest Lab Building - Room B103, 52 Oxford St., Cambridge MA

Sanders Theater - 45 Quincy St., Cambridge MA

http://www.cns.fas.harvard.edu/UGIM2014/

Sponsored by IEEE

M2M Forum, the 14th annual member meeting of the MEMS Industry Group trade association, is your focused opportunity to “lean in” and address the important, universal technical and business hurdles MIG members (and their customers) are challenged with at every step of the MEMS continuum, from the early concept and feasibility stage through to proof-of-concept, design win, successful commercialization, and volume MEMS production.

MIG has arranged an insider’s tour of the world-renowned UC Berkeley Marvell Nanofabrication Laboratory at UC Berkeley. With a focus on wireless communication, RF MEMS, physical sensors and actuators, packaging, power generation, bioMEMS and microfluidics, BSAC offers its impressive list of member companies precommercial and prepublication access to the fundamental research work being done in the center; this exclusive insider’s tour will give M2M Forum participants a flavor for BSAC’s current work and capabilities, and also for BSAC’s future direction.

Organized and produced by:

For more information, visit www.memsindustrygroup.org

The NNIN at the University of Michigan will be hosting a free Workshop entitled ” IntelliSuite Workshop: An end-to-end Solution for MEMS Design and Simulation”.

Click below to register for the workshop.

Topic: IntelliSuite: An end- to-end Solution for MEMS Design and Simulation

Date: February 13th, 2014

Time: 12:30 pm – 4:00 pm

Location: University of Michigan, Windows Training Rooms 1 & 2, James and Anne Duderstadt Center, 2281 Bonisteel Boulevard, Ann Arbor, MI 48109-2094

Agenda:

12:15 Registration and Coffee

12:30 Welcome and Introduction to IntelliSuite v8.7

1:00 Device Simulation

Overview of IntelliSense’s Fastfield Multiphysics simulators and behavioral analysis tool

Live Demo: Simulation of magnetostrictive devices with ThermoElectroMechanical (TEM)

Live Demo: Behavioral and Parametric modeling with SYNPLE

1:45 CleanRoom Process Tool Suite

In-depth look at IntelliSense’s process simulation tools

Live Demo 1: MUMPs process flow generation with IntelliFab and visualizing with FabSim

Live Demo 2: Anisotropic etch simulation with IntelliEtchG

2:15 Break

2:30 Hands-on Tutorials

Comb drive layout design and parametric scripting with Blueprint

Physical process simulation with FabSim

Working with and converting 2D layouts and 3D models

3:30 What’s coming next with IntelliSuite v8.8?

Enhanced Blueprint drawing tools and Hexpresso meshing capability

New process simulation and device simulation features

System simulation enhancements and parametric analysis features

3:50 Wrap-up and closing comments

Presenter: Tom Hall, Applications Manager at IntelliSense

Tom Hall is an Applications Manager at IntelliSense. He has a wealth of experience in MEMS design, CAD/EDA software, FEA simulation, and customer education and training. He has been an integral part of the IntelliSense team by fostering healthy business relationships with current customers and keeping prospective and current users informed about the latest software developments from IntelliSense. Tom has extensive CAD expertise and a strong background in mechanical and manufacturing engineering. Tom holds a degree in Mechanical Engineering from Boston University.

For more information about NNIN @ Michigan, visit them online.

IntelliSense is an exhibitor at the sixteenth Hilton Head Workshops on the science and technology of solid-state sensors, actuators, and microsystems, which will be held on June 8 - 12, 2014. The Hilton Head Workshops have provided a highly interactive forum for North, Central and South American researchers to present and discuss recent advances in microfabrication technologies for sensing and actuation devices and microsystems for physical, chemical, and biological applications. The Workshop will be held at the Sonesta Resort on Hilton Head Island, SC. It will be a single-session meeting, with ample time allotted for discussion of each paper, and with blocks of unscheduled time to encourage informal interactions among participants. There will be ten oral sessions and a contributed poster session. There will also be an open poster session to encourage participants to discuss informally very recent results, work in progress, and results recently presented elsewhere.

This year, besides being open to all researchers from North, Central and South America, the Workshop is open to past attendees of any previous Hilton Head Workshop with verification. This does not apply to past commercial representatives.

Sonesta Resort

130 Shipyard Drive

Hilton Head Island, SC 29928

Phone: 1-843-842-2400

Fax 1-843-842-6503

Sponsored by the Transducer Research Foundation, Inc.

IntelliSense is a leading provider of MEMS design and simulation software. Along with our powerful collection of IntelliSuite tools for MEMS, we have a strong team of designers and fabrication experts that provide a total One-Stop MEMS Solution.

IntelliSense is holding its annual workshop on August 20, 2013. We have invide industry experts from around the world to discuss the issues faced in MEMS design, fabrication and application. IntelliSense MEMS process engineers will discuss several topics such as working with thin-films and issues we face when forming complex structures with wet and dry etching.

Speaker

Professor Kazuo Sato

Introduction

Human Healthcare System Using Ubiquitous Sensors (Ongoing project at Aichi)

Professor Kazuo Sato is one of the world top MEMS experts. He received his Ph.D. at the University of Tokyo in 1982, worked at Hitachi as a senior MEMS executive, and in 1994 as a professor at Nagoya University. He is the founder of the Sato MEMS Laboratory, now the world leading anisotropic wet wtching MEMS lab. He is now working with the Aichi Academy and is also one of IntelliSenses top technical consultants

Jason V. Clark, Ph.D.

Towards Unprecedented Accuracy, Control, and Dexterity in MEMS

Dr. Jason V. Clark, former Purdue University Professor, received his doctorate in 2005 at UC Berkeley. He is a top expert in MEMS analysis and design. He worked at Lawrence Livermore National Laboratory and several other institutions and commercial organizations. As well as being a major contributor to global parametric MEMS analysis and design, Dr. Clark also serves as an IntelliSense VP, responsible for engineering and technical services.

Miguel Gosalvez, Ph.D.

Recent Developments in the IntelliEtch Module Aspect: Etching Corner Compensation

Dr. Miguel Gosalvez is an internationally renowned expert in MEMS process simulation. He earned his Ph.D. at University of Helsinki, Finland in 2003, has worked with various universities in Japan, Europe and Spain, and has also worked at the International Physics Center (DICP). He is currently a senior IntelliSense software development expert, specializing in process simulation.

Location: IntelliSense Park, No. 19 Lixin Road, Nanjing High-Tech Zone, Nanjing, Jiangsu Province

Conference Language: Foreign experts and invited speakers will give sessions in English. Other sessions will be in Chinese.

Cost:Free admittance, includes lunch. Participants will be responsible for accomodation and transportation costs. IntelliSense is happy to provide information and recommendations related to accomodation.

Consulting by: Miss Li

Phone: 18705153556

Tel :025 -66621998-8210

Fax :025 -66,621,978

IntelliSense is exhibiting at the 26th IEEE International Conference on Micro Electro Mechanical Systems (IEEE MEMS 2013) which will be held in Taipei, Taiwan on January 20 – 24, 2013 at the Taipei International Convention Center (TICC). IEEE MEMS is one of the premier annual events reporting research results on every aspect of microsystems technology. This conference reflects the rapid proliferation of the commitment and success of the microsystems research community. Recently, the IEEE MEMS Conference has attracted more than 700 participants, 950+ abstract submissions and has created a forum to present over 300 peer-reviewed, top-quality papers in podium and poster/oral sessions.

Conference organized by:

For more information, visit www.mems2013.org

IntelliSense will be exhibiting at TRANSDUCERS 2013 in Barcelona, Spain. The Transducers conference is the largest multidisciplinary conference on Microsensors, Microactuators and Microsystems, with about more than 1000 attendees from university, research institute, government and industry who gather every two years to exchange the latest advances in the field. The coming Transducers13 conference is the 17th international conference on solid-state sensors, actuators and Microsystems of the TRANSDUCERS conference series started at 1981 in Boston (USA), and it is the first time for this conference to be held in Spain. The conference will feature four days of presentations and posters highlighting the latest and most technically advanced work in mechanical, optical, chemical, and biological devices and systems using micro and nano technology. Work of both a fundamental and applied nature will be featured.

For more information, visit www.transducers-eurosensors2013.org

At MIG’s Member-to-Member (M2M) Forum, members will gather to discuss the opportunities and challenges for the entire supply chain for MEMS in healthcare, medical, and biomedical applications. MEMS and medical industry experts, leading academic researchers, will provide insight and strategies to successfully integrate MEMS into medical devices. This year, the M2M forum will take place right in IntelliSenses backyard! MIG has arranged a historic, one-of-a-kind insider’s tour of the world renowned labs of MIT. The tour will begin with a look inside some of MIT’s most innovative labs working across multidisciplinary fields within BioMEMS and FluidicMEMS and end with an invited speaker and networking session. They don’t roll out the red carpet for just anyone… Only MIG!

Organized and produced by:

For more information, visit www.memsindustrygroup.org

IntelliSense will be a sponsor this year at the MEMS Executive Congress, the preeminent annual conference and networking event for the MEMS industry. It is a unique professional forum at which executives from companies designing and manufacturing MEMS technology sit side-by-side with their end-user customers in panel discussions and networking events to exchange ideas and information about the use of MEMS in commercial applications. By creating an intimate forum for decision-makers, the goal of the Congress is to define, collaborate on, and grow the global MEMS market by connecting the MEMS supply chain (including device manufacturers, designers, equipment & material suppliers) with end-users and potential end-users of MEMS.

Organized and produced by:

For more information, visit www.memsindustrygroup.org

IntelliSense will be exhibiting at the MEMS 2014 conference in San Francisco from January 26-30. Every year, the IEEE MEMS Conference attracts participants from around the globe and provides attendees an excellent environment for exchanging ideas, making connections and discovering new products. This year will be no different. We will give the MEMS 2014 participants a first look at IntelliSuite 8.8, the newest software package from IntelliSense. Be sure to meet us and check it out at Booth 24!

Over the past twenty-five years, the IEEE MEMS Conference series has been the flagship annual event of the MEMS community. The 27th IEEE International Conference on Micro Electro Mechanical Systems (MEMS 2014) will report research and development results on every aspect of MEMS and Microsystems Technology, reflecting on the strong commitment and continuing success of the international MEMS community. In recent years, the IEEE MEMS Conference has created the forum for over 200 top-quality papers, selected from over 800 abstract submissions, in non-overlapping oral and poster sessions, and attracted more than 700 participants. Its single-session format provides ample opportunity for strong interaction between attendees, presenters and exhibitors.

Sponsored by:

Conference Location:

Hyatt Regency San Francisco

5 Embarcadero Center

San Francisco, California 94111 USA

sanfranciscoregency.hyatt.com

More information can be found at www.mems2014.org

Micro-Electro-Mechanical Systems, or MEMS, is a technology that in its most general form can be defined as miniaturized mechanical and electro-mechanical elements (i.e., devices and structures) that are made using the techniques of microfabrication/ Nano fabrication. These techniques are comprehensively used in various engineering applications. The course is aimed for educating participants about the fundamentals of these techniques and at the same time extends to expose them to the recent advancement in this area. Owing to the interdisciplinary nature of this course, participants across the disciplines will be able to attend, appreciate and augment their knowledge to keep with the emerging advanced techniques. The course will help mentors to further deliver its contents to their students and will endow budding researchers with state-of-the-art tools to improvise their research.

The aim of this three days short term course (STC), is to train and orient the faculty & Scholars to learn these techniques in appealing way. This will provide a first-rate education, that is meaningful in the workplace as well as in post graduate education leading to a research and development oriented career. The program has been developed with unique approaches to convey information more effectively and enable the visualization and application of MEMS Design techniques.

Day 1:

1. Introductions to MEMS technology.

2. Introductions to IntelliSuite Software.

3. Simple MEMS designs using IntelliSuite software.

4. Question and answer sessions.

Day 2:

1. Design of MEMS based Cantilever beam using fabrication process flow.

2. Simulation on MEMS based Cantilever beam.

3. Results and discussions on the device simulations.

4. Design of MEMS based capacitive pressure sensor.

5. Simulation on MEMS capacitive pressure sensor.

6. Results and discussions on the device simulations.

Day 3:

1. Design of A Cross Injector.

2. Device Simulation - Electrophoresis Analysis.

3. Results and discussion on the device simulation.

4. Design of MEMS based Gyroscope.

5. Device simulation on Gyroscope.

6. Results and discussion on the device simulation.

Inaugural: 7th October at 9.30 AM

Valediction: 9th October at 4.30 PM

Venue: Resonance Seminar Hall, Department of Electronics Engineering

Registration is free for faculty as well as Scholars (PhD/M.Tech). The self contributory amount Rs. 500/- will be used for kit, high tea, working lunch and other expenses and is mandatory each participant.

Last date of receiving completed registration form is 30th September 2013. Limited seats are available. Hence, participants are advised to register at the earliest to avoid any inconvenience. Applications through email are also acceptable. Selected participants will be informed via email only.

Address for Correspondence:

Organizing Secretary (MDTA-2013) Mr. Deepak Bhatia

Department of Electronics Engineering

Rajasthan Technical University, KOTA

Kota-324010 (Rajasthan)

Email: keshav_eck26@yahoo.com,

Phone: 09414317401,0744-2473955-3056

Fax: 0744-2473040

Micro- and Nano- Electromechanical System (MEMS/NEMS) are the examples of integration of mechanical elements with sensors, actuators and electronics through a variety of micro and nano fabrication tool kit. MEMS/NEMS based devices have been developed and are being developed for the applications in various sectors such as consumer, medical, defense, space, communication etc. The MEMS market is still one of the fastest growing zones of the semiconductor industries. This five day workshop cum certificatecourse on MEMS and NEMS will cover a wide range of topics right from the fundamentals to applications.

Course objectives:

For more details, visit the event website: www.iithmems.webs.com.