Welcome to IntelliSuite: Your Complete MEMS Design and Simulation Solution

At IntelliSense, we're dedicated to providing cutting-edge solutions for MEMS design and simulation. Welcome to IntelliSuite, where innovation meets precision engineering.

Our IntelliSuite software revolutionizes MEMS design, offering comprehensive tools for every stage of the design process. From conceptualization to prototyping, our intuitive platform empowers engineers to create MEMS devices with unparalleled efficiency and accuracy.

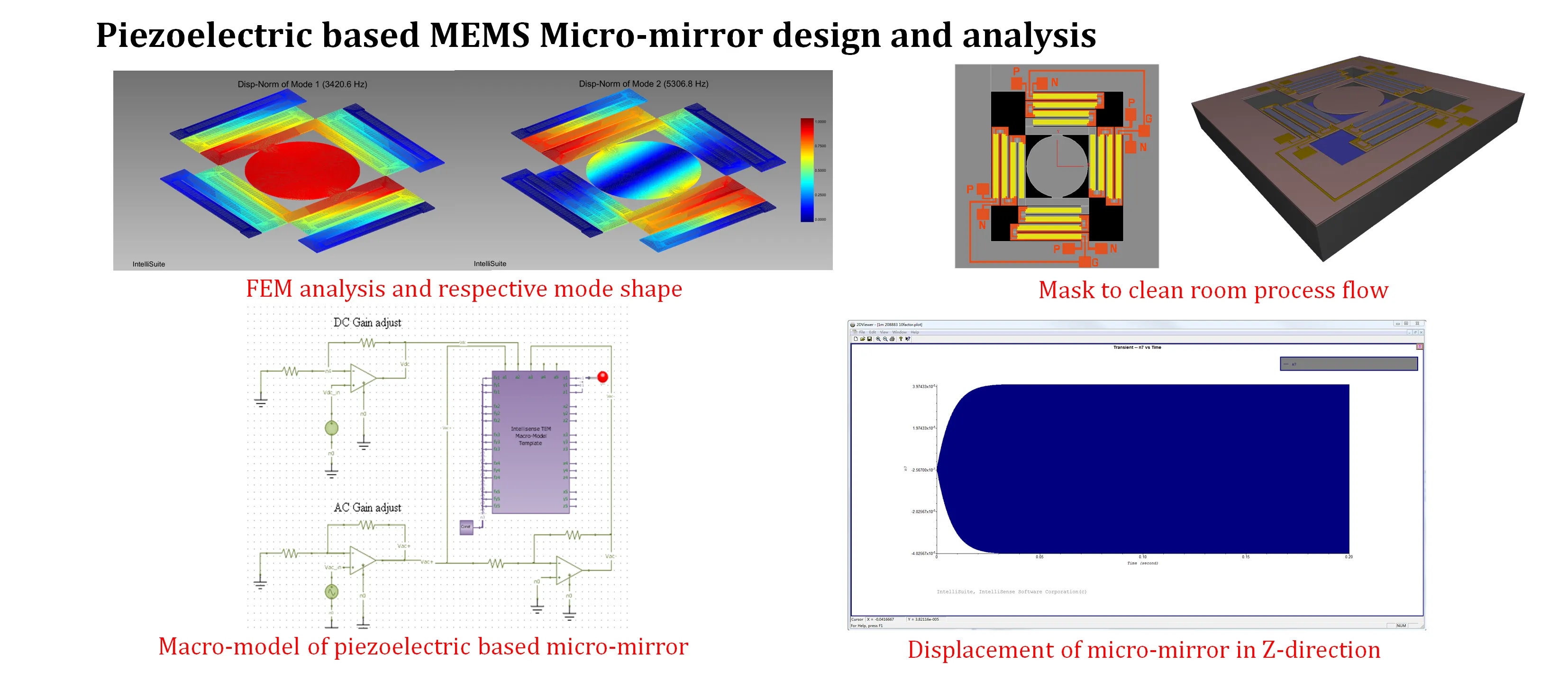

With IntelliSuite, you can simulate the performance of your MEMS devices with precision. Our advanced simulation capabilities allow you to analyze various parameters, such as motion, stress, and thermal behavior, ensuring optimal performance under real-world conditions.

Ready to revolutionize your MEMS design process? Explore the possibilities with IntelliSuite and experience the future of MEMS engineering today.

IntelliSuite is a tightly integrated design environment that will link your entire MEMS organization together. Built to scale from a point tool to an organization-wide tool, IntelliSuite unifies various engineering and manufacturing tasks into a single living design environment.

Designed around collaboration, IntelliSuite allows the design, process,packaging and system teams collaborate on MEMS devices that can be prototyped and manufactured with fewer costly iterations.

After close to two decades in continuous development, IntelliSuite now boasts the widest range of features available in a MEMS tool, and remains unsurpassed in its simulation capabilities, robustness and ease of use. That’s why IntelliSuite serves users in more than 35 countries, including the majority of the top MEMS manufacturers, research organizations and MEMS universities. And that’s why it’s the industry standard software for MEMS.

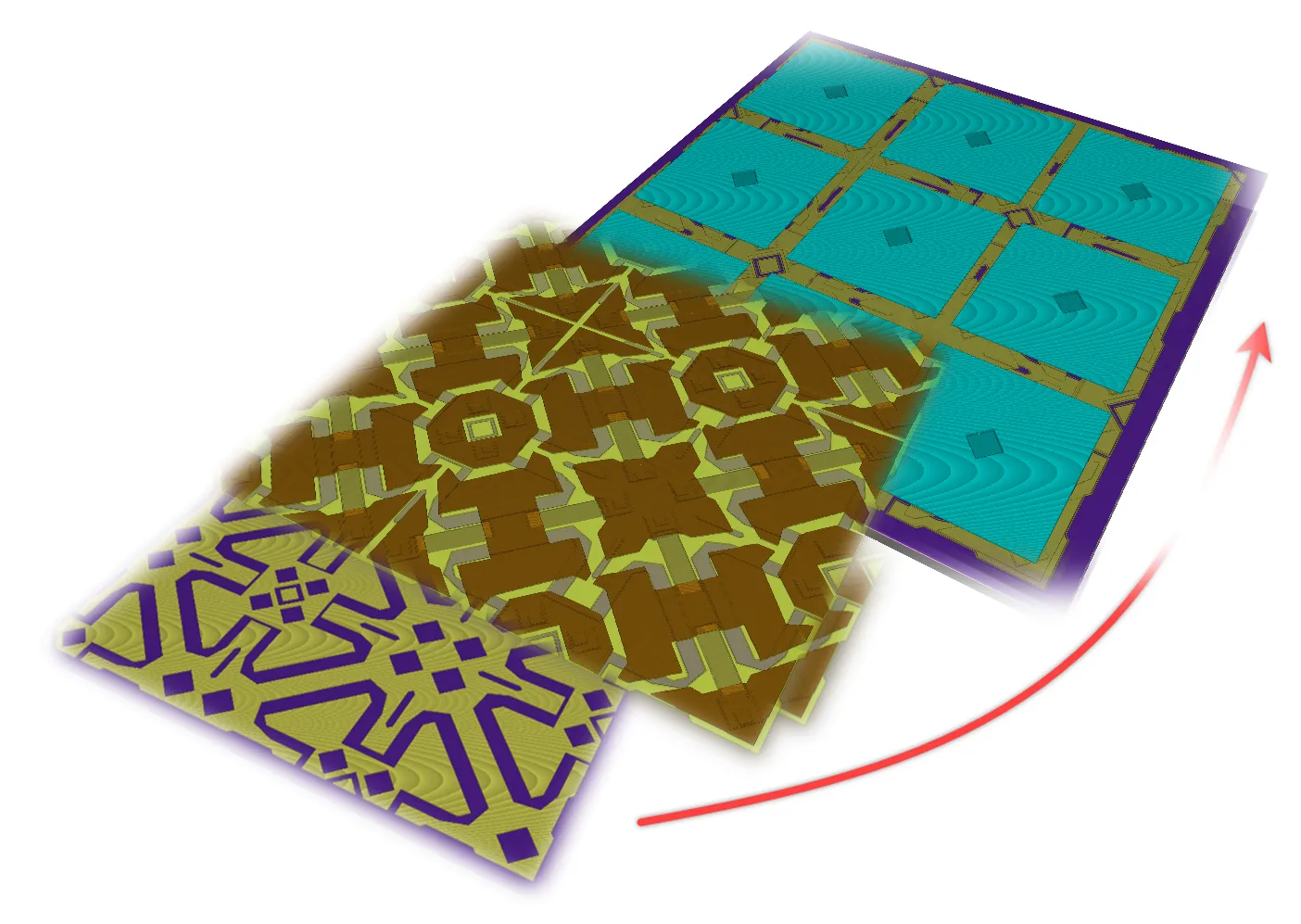

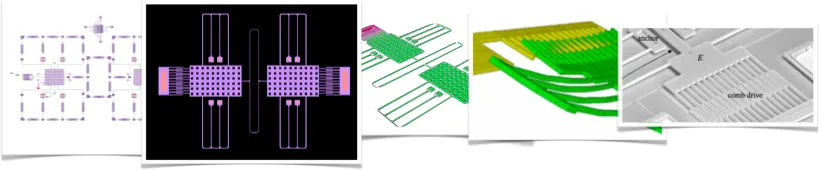

IntelliSuite contains a wide range of closely integrated tools to seamlessly go from schematic capture and optimization to design verification and tapeout. A flexible design flow allows you to start your design at either schematic, layout or 3D level.

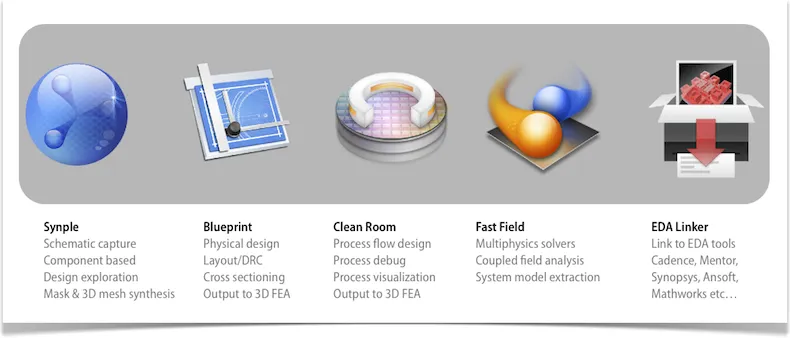

IntelliSuite consists of a number of advanced tools that work together. For instance, Synple allows you to capture your MEMS at a schematic level, much like SPICE for electrical circuits. Your design can then be quickly iterated and optimized at different granularities. Sophisticated synthesis algorithms can automatically convert your schematic into mask layout, 3D or better yet a meshed structure for full multiphysics analysis.

Blueprint, is a physical design tool that incorporates advanced layout, design rule check, cross-section exploration, and automated mask to hex mesh capabilities. CleanRoom process suite allows you to create and debug your process flow and your mask set before you enter the clean room. It allows you to make virtual prototypes to save costly fabrication mistakes. Advanced Fastfield Multiphysics tools feature fully coupled electrostatic, mechanical, fluidic, and electromagnetic engines. Advanced Model Order Reduction based Extraction techniques capture electromechanical, fluidic and damping behavior into compact models, while EDA Linker seamlessly links IntelliSuite to other leading EDA tools.

IntelliSuite comes with all the design tools required to take your product from concept to market. We ship a full complement of tools with which you can perform process modeling, device layout and device analysis. In fact, IntelliSuite comes standard with completely coupled electrical, piezo-electrical, mechanical and thermal analysis tools for executing linear or non-linear static or transient analysis, while optional modules for electromagnetic, fluidic and system analysis are also available.

At IntelliSense, we constantly monitor the latest developments in the MEMS industry for new features and capabilities. And if we haven’t already provided everything you’re looking for, we can develop customized features to meet your specific needs.

Year to date, countless MEMS professionals have successfully utilized IntelliSuite to design and bring many MEMS to market. If you’re a MEMS professional, IntelliSuite will give you the unlimited creative freedom to realize virtually any MEMS you can dream up. Use it to design and develop your next big or small idea!

As an engineering manager, IntelliSense provides you all the tools you need to monitor every aspect of the MEMS development. You can explore MEMS development at different granularity from high-level cost estimates and yield projections to mid-level design analysis studies, low-level process flow or metrology data. Intended for use company-wide, IntelliSuite supplies an effective mechanism to consolidate your broad organizational MEMS knowledge in one repository.

With IntelliSuite, we furnish device designers like you with the comprehensive design exploration tools necessary to follow your unlimited creativity. That's why IntelliSuite includes SYNPLE and a full suite of FEM/BEM analysis tools that will allow you to design such diverse MEMS as sensors and actuators, RF and optical MEMS, and microfluidic devices and biosystems.

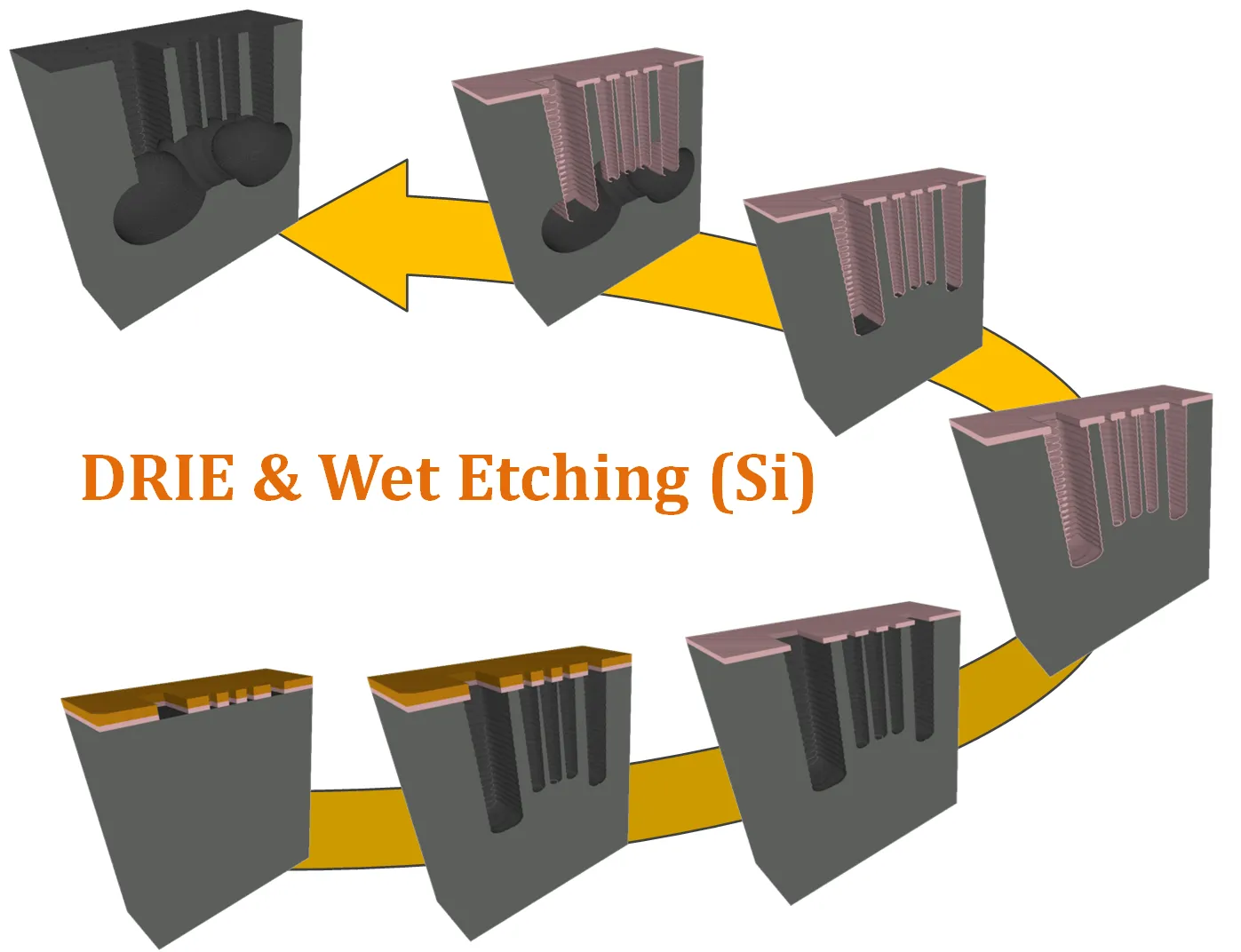

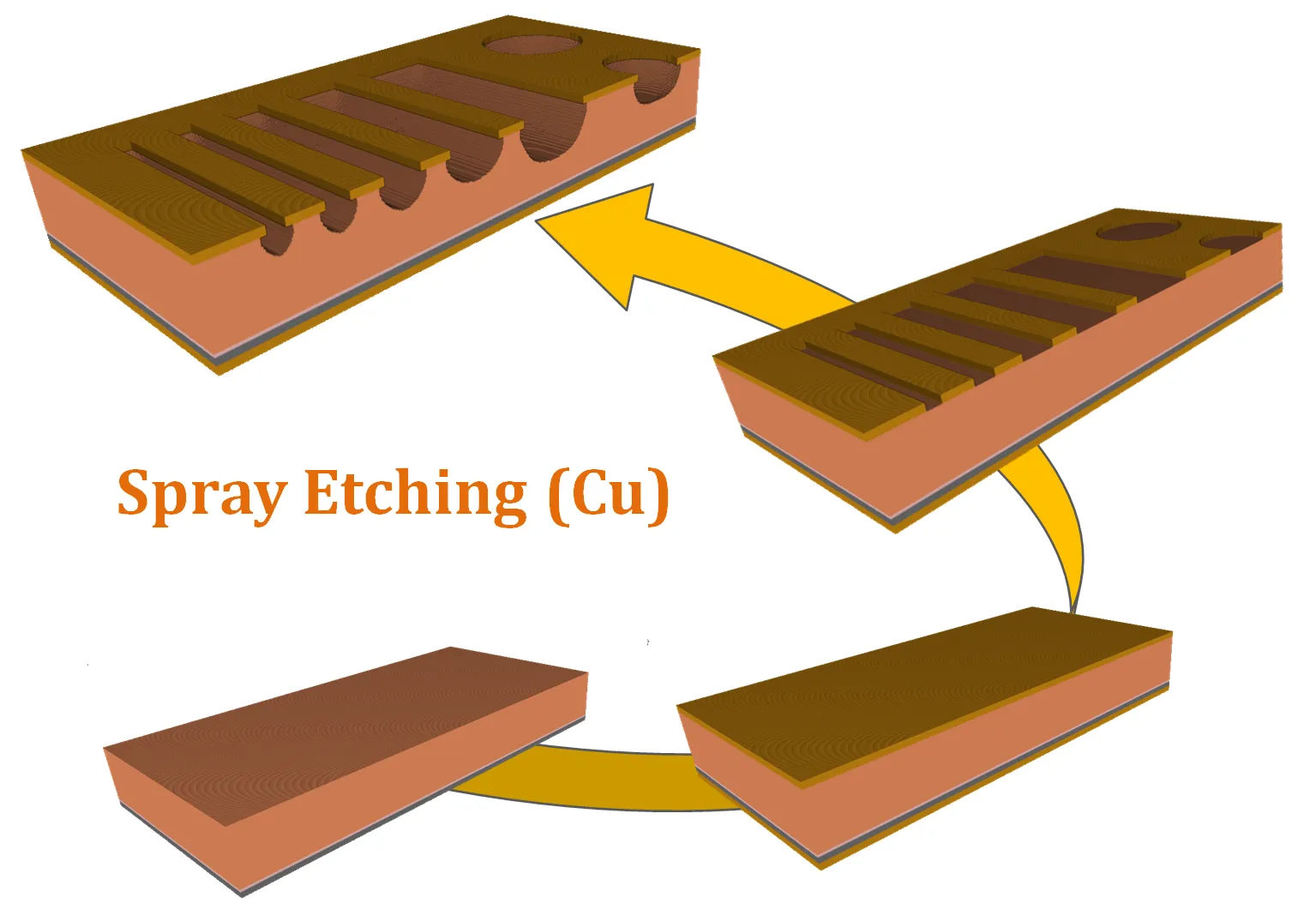

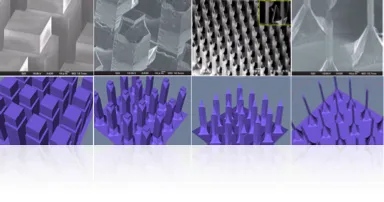

If you are a process/manufacturing engineer, our design for manufacturing (DFM) tools grant you the capability to implement your first-time right designs. The across-the-board selection of IntelliSense process tools include virtual prototyping and 3D traveler visualization, thin film material characterization and optimization tools and databases, wet and dry-etch simulators, and Monte Carlo tools for yield prediction. So, whatever your process engineering goals maybe, our process-specific tools will help you achieve them.

IntelliSense enables electrical and system engineers to create and simulate complex MEMS models with exceptional ease. Thanks to SYNPLE, MEMS system design is as fundamental as dragging and dropping, and wiring the schematic. In addition, EDA Linker automatically generates high fidelity HDL (Verilog, VHDL, Simulink or SPICE) models of the MEMS and package to fit your favorite Mixed Signal simulator from Cadence, Mentor, Synopsys, Mathworks or Tanner.

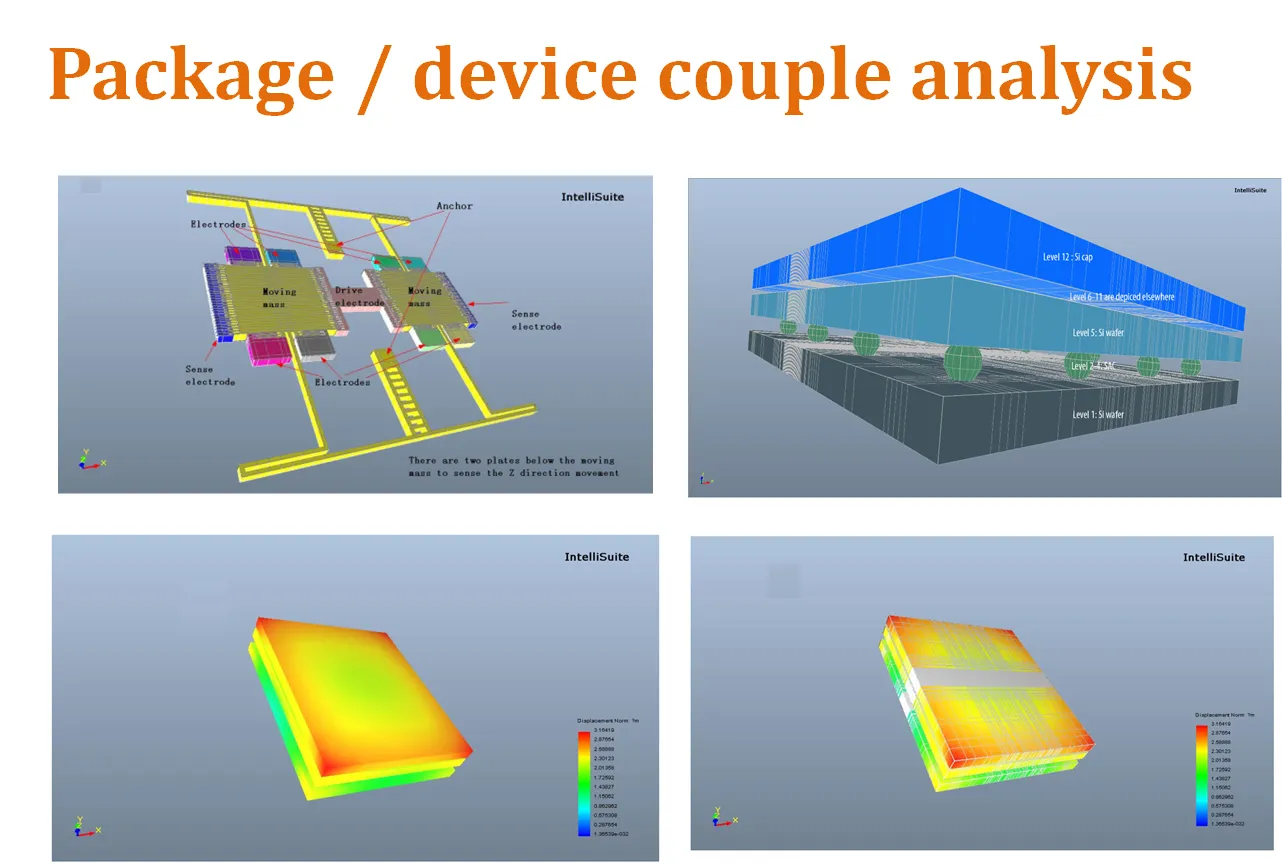

As a packaging engineer, IntelliSense offers you tools for thermal, mechanical and high-frequency modeling of your devices. Parametric scripting capabilities allow you to effortlessly create a range of packages, such as SOICs, DIPs, QFPs etc. What's more, wafer-level encapsulation and related stress analyses may be performed with ease. As a result, you can wrap up your projects quickly and efficiently!

Working together, IntelliSuite and SYNPLE give test engineers a straightforward method for creating parametric test structures and design of experiments (DoE) during the layout process. What's more, our analysis and system simulation tools allow you to perform a vast subset of MIL-STD (750/883), JEDEC (JESD22) and Telcordia (Belcore) tests in software before the actual fabrication. For success in your next test, turn to IntelliSuite!

IntelliSenses software architecture is based upon a unique combination of the best of bottom up process-driven design and top down synthesis. Top down methodology allows you to quickly explore a wide range of design options, while bottom up design provides the accuracy to produce first-time right silicon.

The accurate bottom up process-driven design and top down schematic-driven synthesis are combined to get you to your designs faster and with less process iterations.

Download the whitepaper to learn how you can get to first time right design!

State-of-the-art schematic capture and simulation tools allow you to take a hierarchical approach to the design space. SYNPLE provides a large multi-domain library of electrical, mechanical, thermal, and MEMS libraries. These elements may be combined in an effortless drag-and-drop fashion and then wired to create schematics of multi-domain systems. As a result, you can quickly survey a large design space before initiating a detailed analysis and verification process. Users can perform device level optimization using Design of Experiments (DoE), Robust Design or other techniques.

Built in place and route and synthesis algorithms can be then used to convert the schematic into a mask layout or an optimally hexahedral meshed model ready for full 3d analysis.

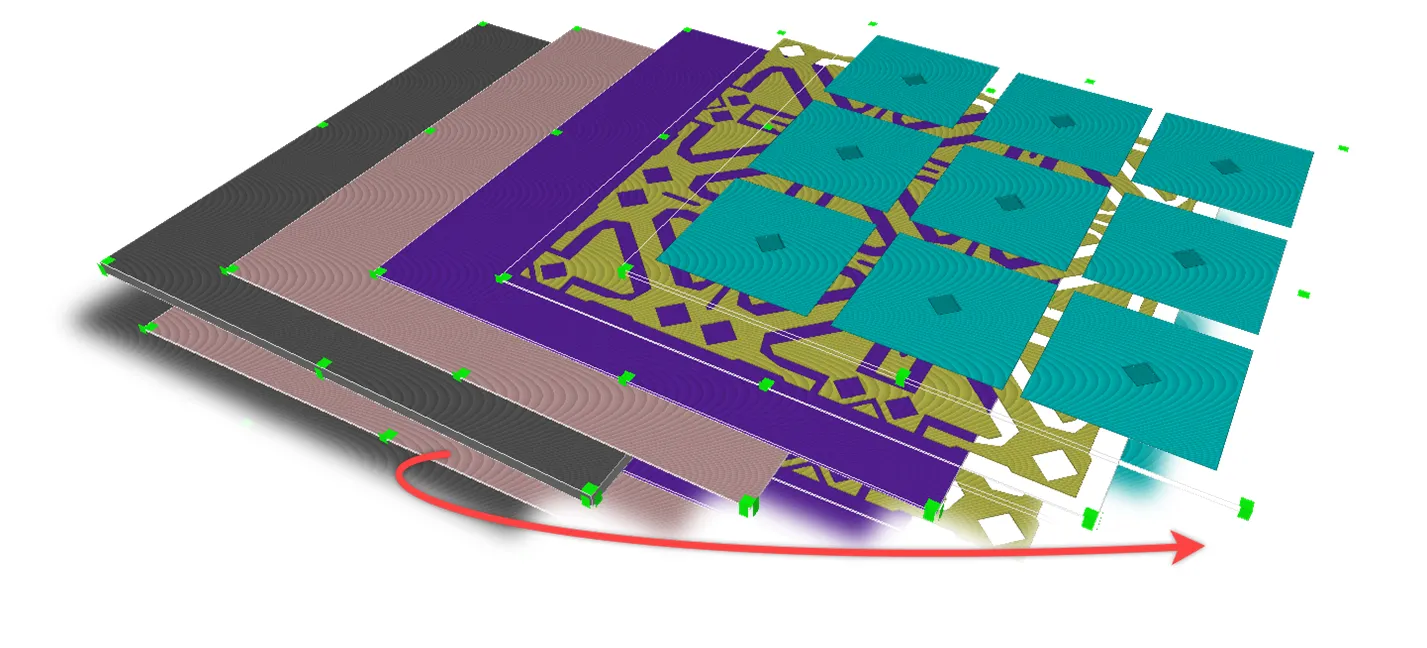

IntelliSuite’s bottom up architecture is based upon process

elements familiar

process steps, such as photolithography, thin film deposition, selective etching

form the basis of understanding the final device geometries. By systematically

building the prototype in IntelliSuite, you can identify costly process bugs

before entering the fab, which ultimately saves time and money. The process

steps, combined with the mask geometries, can be used to build the final virtual

device.

Blueprint, an advanced layout and TapeOut all angle Physical

Verification (DRC) tools allow you to layout complex masks with ease. Automated

hexahedral meshing techniques can be used to construct robust meshes for

analysis.

IntelliSuite features a comprehensive material database, which allows you to

understand material properties like conductivity, film stresses and mechanicall

strength as a function of processing parameters. Subsequently, this enables you

to produce more realistic models.

Etching has always been a bugbear in MEMS

technology. We’ve provided wet and dry etch simulators — a full anisotropic wet

etch simulator for creating realistic models of your KOH, TMAH or EDP etches,

and a dry etch simulator for simulating RIE/ICP and Bosch etch processes.

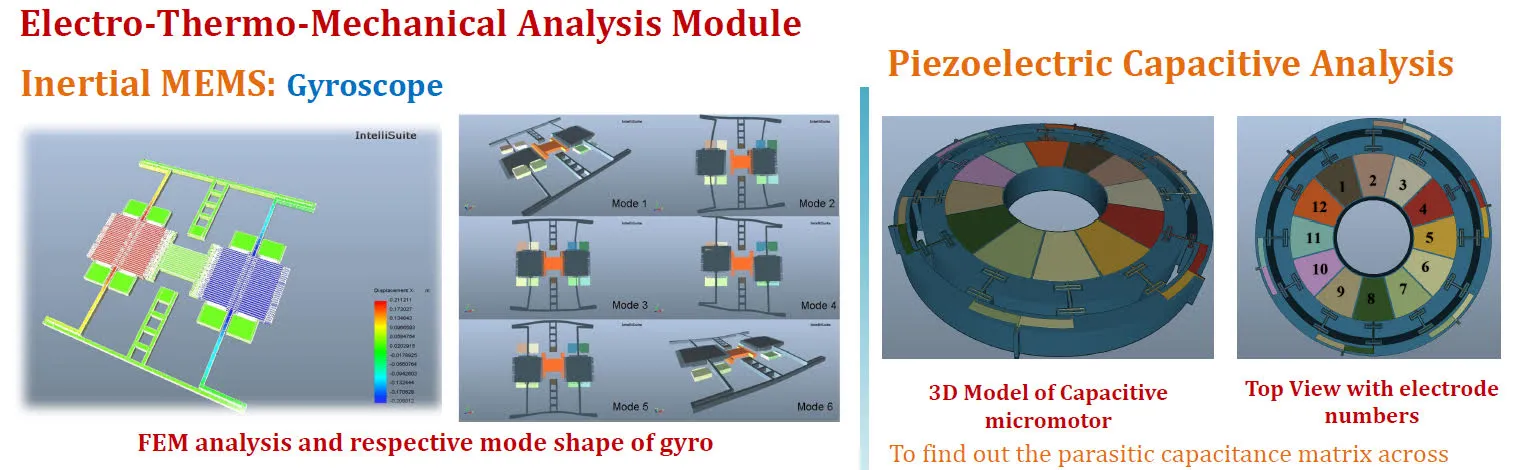

IntelliSuite comes with all the modules that you need to perform fully coupled thermal, electrostatic, fluidic and mechanical simulation and piezo simulation of the MEMS device. Optional modules for electromagnetic and fluidic/bioMEMS analysis are available. Out of the box, you can analyze almost any MEMS device that you can dream up! The IntelliSuite virtual device can be subjected to a combination of inputs, such as electrostatics, electromagnetic fields, temperature, mechanical stresses and pressures, and fluid flow.

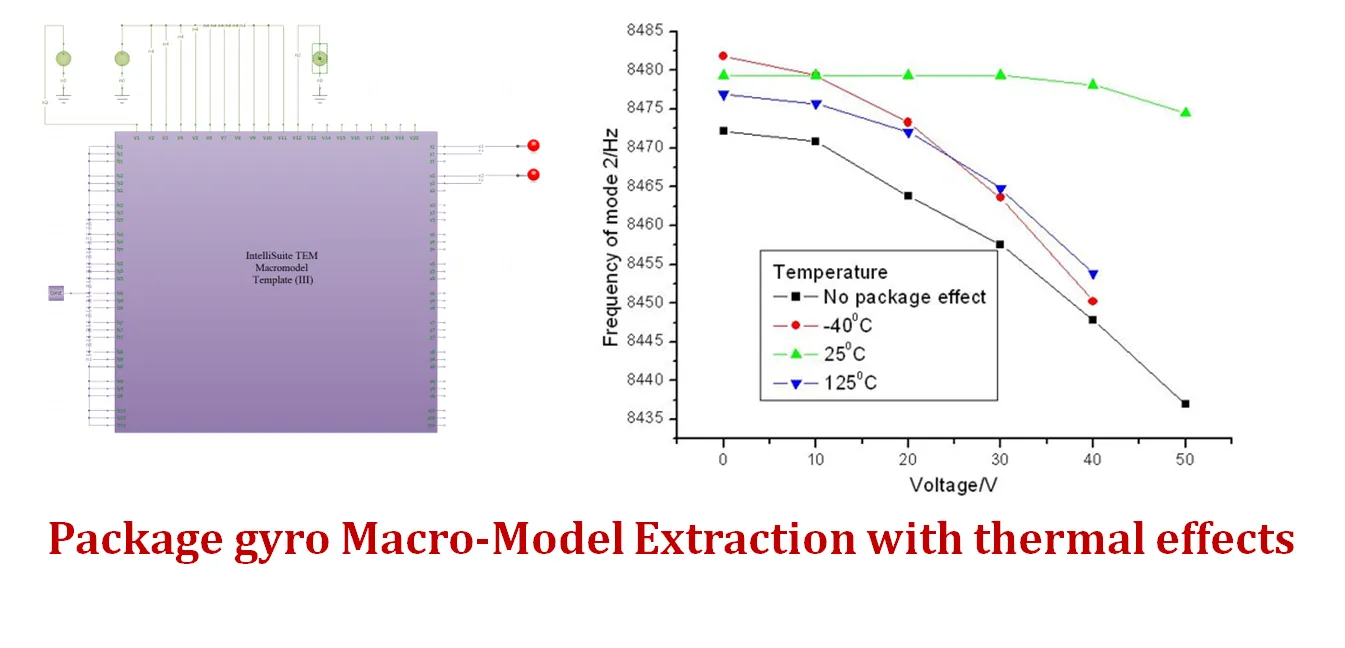

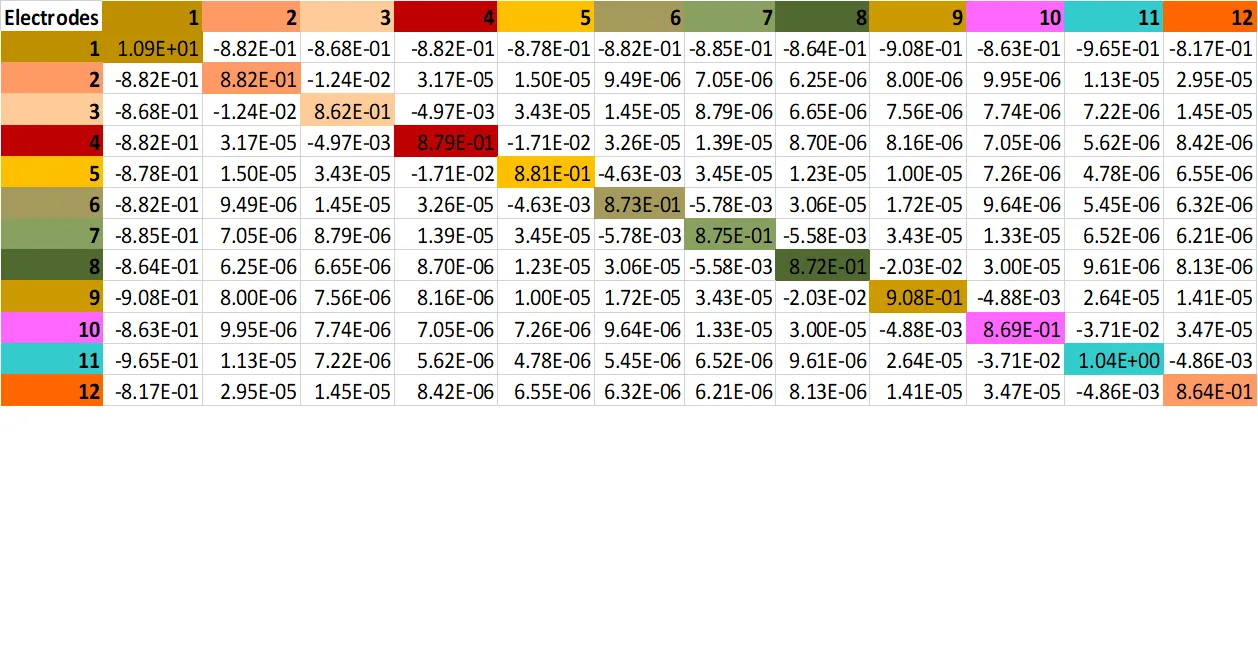

IntelliSuite uses state-of-the-art model reduction techniques to automatically create compact system models from large finite element models. System models encompass coupled electro-mechanical behavior including stress stiffening, electrostatic softening, packaging effects, fluidic and other sources of damping. These accurate compact models can be exported to VHDL, Verilog-A, SPICE, Matlab and other tools for full MEMS-ASIC co-simulation.

IntelliSuite is designed to be an open system that’s compatible with other tools. We speak a wide range of file formats, including DXF and GDS II (for mask import and export), IGES and PATRAN (solid model or FEA input), ABAQUS, ANSYS (FEA model import and export) and Touchstone (high-frequency analysis). Our macro-models can be used in conjunction with H-SPICE, SPECTRE, HFSS, ADMS, ELDO, Matlab/Simulink, SystemVision or other VHDL-AMS, Verilog-A or SPICE based tools for further system integration. All the analysis results and solid models can be exported to AVI or JPG format to enhance your next presentation or report. In addition, all of our file formats are rigorously documented and available, which means that, like other tools on the market, vendor lock-in is never an issue.

IntelliSuite was designed in a modular fashion so that you can choose the functionality that you want without overpaying. Our flexible purchasing policy allows you to buy individual modules at a later stage to add to your functionality.

Popular options include the following bundles:

Blueprint, TapeOut, and CSViewer

includes all the process modules

3DBuilder, Fastfield ThermoElectroMechanical Module and EDALinker

3DBuilder and Microfluidics Analysis

Synple, Hexpresso and MEMSynth

Export to Microsoft PowerPoint is a powerful new feature in IntelliSenses Clean Room suite of process simulation and visualization tools. IntelliSenses new layout editor BluePrint allows you to link to a process flow and look at a 2D cross-section of your mask at any orientation. These cross-sections at each process step can be exported to PowerPoint for easy documentation and sharing.

FabViewer, our 3D process visualization tool, can also export a PowerPoint file with a slide for each process step. Also included at the end of the document is a helpful summary of the lithography, deposition, and etching steps.

IntelliSuite design tools are scriptable, enabling you to create complex designs through scripting. We have built in a language-independent scripting engine so that you can script with the language of your choice.

IntelliSuite ships with an extensive parametric library of commonly used MEMS elements, ranging from linear and rotary comb drives to release plates and springs. In addition, we have included a large library of test elements, such as stress and stress gradient indicators, Guckel rings and Euler beams for measuring the material properties of your thin films.

IntelliSuite applications can be tailor fit to your needs or whims. Everything from Menus to keyboard shortcuts and accelerators, to icons and toolbars to application layouts can be customized to fit your precise needs.

If you are migrating from another tool, you can customize toolbar layouts and keyboard shortcuts so that you can apply your muscle memory without skipping a beat.

GDSII, DXF, CIF, GERBER, RS-247, EMK, HOLES

IGES, SAT, VRML, GEOM, DXF, RAW/RAWIV (Voxel)

PowerPoint (PPT), PNG, JPEG, RAW, RAWIV

UNV, PAT, CDB, SAT, NEU (Ansoft, Ansys, ABAQUS, Nastran, Simulia)

Verilog, VHDL-AMS, PSPICE, HSPICE, SIMULINK (MEX), TOUCHSTONE

ASCII, CVS, PLT (Tecplot), ODB (Simulia), AVI, RAW

Print Quality:

IntelliSuite ships with a number of high quality application notes and examples to help you get started with ease. Whether you are designing a gyro or an electrophoretic channel, there is an app note that will get you off the starting block quickly.

Download:

Bill Tangs seminal resonator makes a great learning tool! Think of it as an introductory course in MEMS design.

Download:

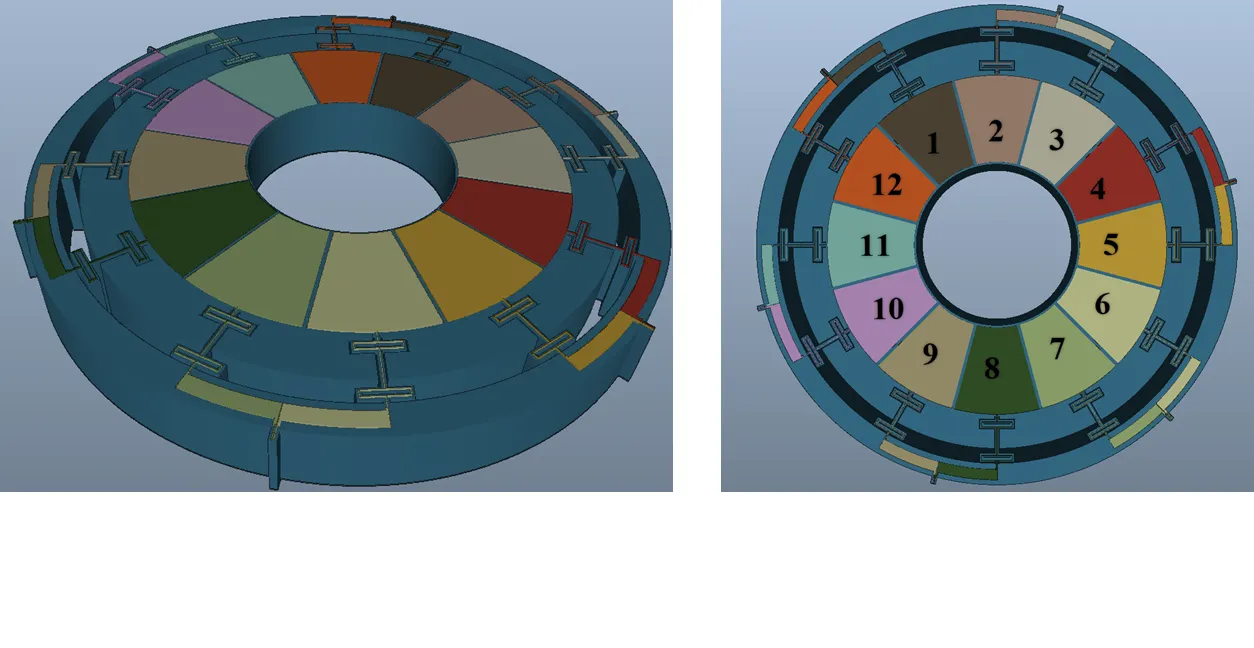

Design methodology for high performance gyros. Illustrates a typical design cycle from conception to electronics integration.

Download:

Demonstrates Fluid Structure Interaction (FSI) capabilities for design of a piezoelectrically driven pump

Download:

Learn about how IntelliSuite handles anisotropic and orthotropic materials such as GaAs, Quartz and Silicon.

Download:

Sub harmonic signals can excite a MEMS structure in non-intuitive ways. Learn how to model sub-harmonics using non-linear theory.

Download:

Illustrates and benchmarks macromodel extraction of fluid damping. Learn how to incorporate fluidic spring and damping effects in your models.

Download:

Learn how to model reaction dynamics coupled with electrophoretic flow

Download:

Modeling the Classic Cross Injector in Microfluidics